Material handling and logistics automation is yet another example of automation in manufacturing. Automated material handling systems like conveyors, AGVs (Automated Guided Vehicles), and AMRs (Autonomous Mobile Robotics) help transport raw materials and finished products between different areas of the manufacturing plant.

The Benefits of Investing in Automation

Industrial automation has become a crucial component of manufacturing and production processes. The benefits of automation in manufacturing include streamlining operations and leveraging technological advances for:

Increased productivity: By automating tasks that were previously reliant on human operators, manufacturing companies can achieve significant improvements in productivity. Automated systems can perform tasks more efficiently and accurately, resulting in faster production times and increased output. This allows businesses to meet demand without sacrificing quality.

Improved safety: In industrial environments where heavy machinery and complex processes can pose a risk to workers, automation can improve overall safety. By automating dangerous or repetitive tasks, companies can reduce the risk of accidents and injuries. Additionally, human machine interfaces (HMIs) allow for remote monitoring, reducing the need for workers to be physically present in hazardous environments.

Incredible savings: While the initial investment in automation systems can be significant, the benefits ultimately lead to impressive cost savings. Automated systems reduce labor costs, increase efficiency, and minimize waste. Additionally, automation solutions help companies meet compliance standards and reduce the risk of operational errors, which can result in costly fines or product recalls.

Solve Pain Points with Automation

Manufacturing companies face numerous challenges in their operations including process inefficiencies, cost control, and quality assurance. Industrial automation addresses these problems by streamlining processes and optimizing productivity. Here are three common pain points automation can help to solve:

Controlling manufacturing processes: Efficiency is essential in manufacturing. Inefficient processes can lead to significant downtime, waste, and lost productivity. Automation helps manufacturing companies optimize their processes by reducing lead time, minimizing human error, and automating repetitive tasks. Automated systems can collect data in real time and produce analytics, allowing engineers to identify bottlenecks in the production line and optimize the process to achieve optimal efficiency.

Recouping high costs: The cost of production in manufacturing is very high. Automation can reduce costs by minimizing the need for human resources. Automation can reduce the number of errors caused by human oversight, ultimately lowering operational costs and maximizing profitability. Additionally, automated systems can operate 24/7 without breaks, which leads to enhanced productivity and reduced downtime.

Maintaining product quality: Ensuring product quality is a high priority for any manufacturing company. Automated systems like programmable logic controllers (PLCs) can control production processes with high precision, increasing consistency and accuracy. PLCs can maintain specific pressure, temperature, and other process variables, ensuring consistency throughout production runs, and reducing the likelihood of defects and rework.

How RōBEX Brings Complete Solutions to the Market

RōBEX is a leading automation specialist who can help manufacturing companies looking to introduce or expand automation products in their operations. The company offers a wide range of industrial automation systems which can be tailored to meet the specific needs of any manufacturing operation.

RōBEX is a leading automation specialist who can help manufacturing companies looking to introduce or expand automation products in their operations. The company offers a wide range of industrial automation systems which can be tailored to meet the specific needs of any manufacturing operation.

Our solutions are designed to improve manufacturing efficiency, accuracy, and safety.

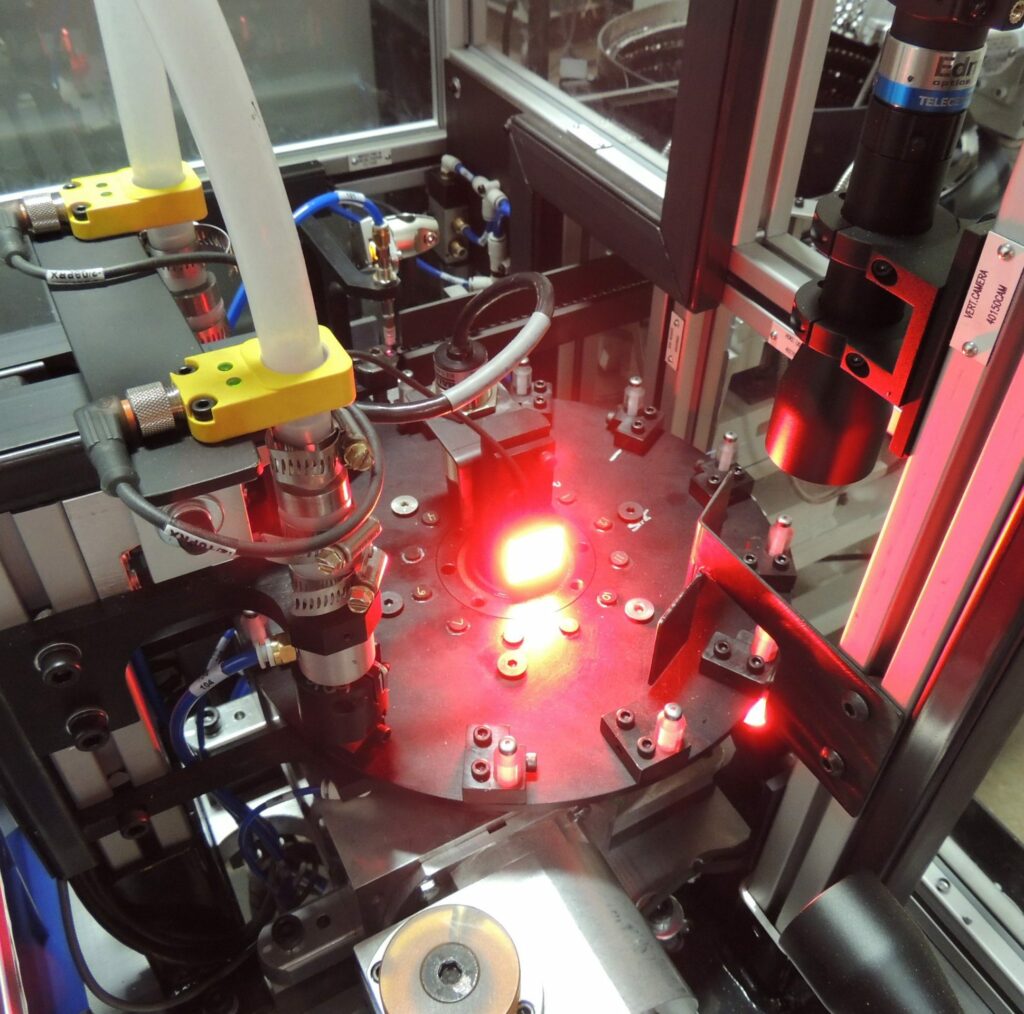

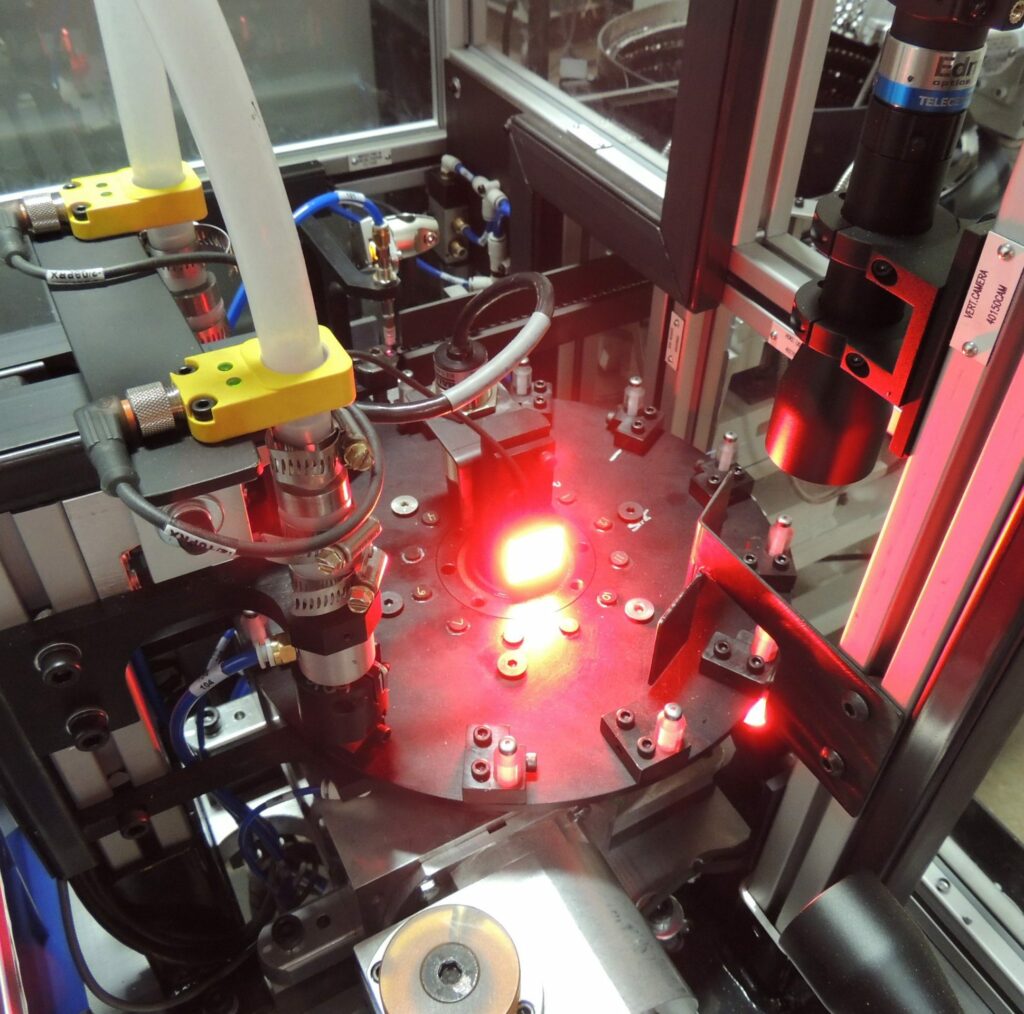

Using RōBEX’s industrial automation systems, manufacturers can reduce labor costs, increase production capacity, and improve product quality with offerings ranging from machine vision and control engineering to motion control and instrumentation.

Our company’s systems are designed to be flexible, scalable, and easy to use, making them ideal for both large and small manufacturing operations.

RōBEX’s expertise in industrial automation allows us to offer complete solutions to the market.

By providing a fully integrated system, we help reduce the complexity and costs associated with introducing or expanding automation products in manufacturing operations. With RōBEX’s industrial automation systems, manufacturing companies can improve their bottom line, reduce downtime, and increase productivity.

Contact us to learn more about how RōBEX can be your premier industrial automation partner.

The benefits of automation technologies vary depending on the specific application and industry.

The benefits of automation technologies vary depending on the specific application and industry. RōBEX is a leading automation specialist who can help manufacturing companies looking to introduce or expand automation products in their operations. The company offers a wide range of industrial automation systems which can be tailored to meet the specific needs of any manufacturing operation.

RōBEX is a leading automation specialist who can help manufacturing companies looking to introduce or expand automation products in their operations. The company offers a wide range of industrial automation systems which can be tailored to meet the specific needs of any manufacturing operation.