5 Benefits of AMR/Cobot Integrations

Here are five advantages of integrating Autonomous Mobile Robots (AMRs) and Collaborative Robots (cobots), which can greatly benefit your warehouse or factory operations while ensuring compliance with regulations:

Labor Reduction

Companies have long relied on automated processes to optimize material handling coordination.

Experts tracking automation development have consistently predicted an increase in the use of machines for production. In the past, implementing automation on small or medium-sized manufacturing assembly lines was cost-prohibitive.

However, advancements in industrial robot integration have made automation more accessible, especially in industries like food and beverage packaging. With rising labor costs and a decreasing workforce, automation has become a necessity.

Data Collection

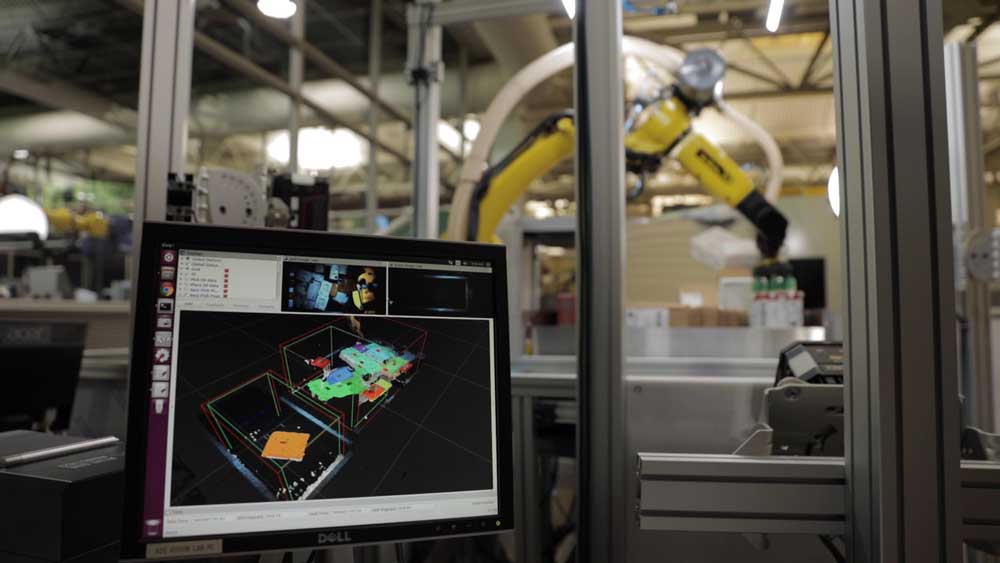

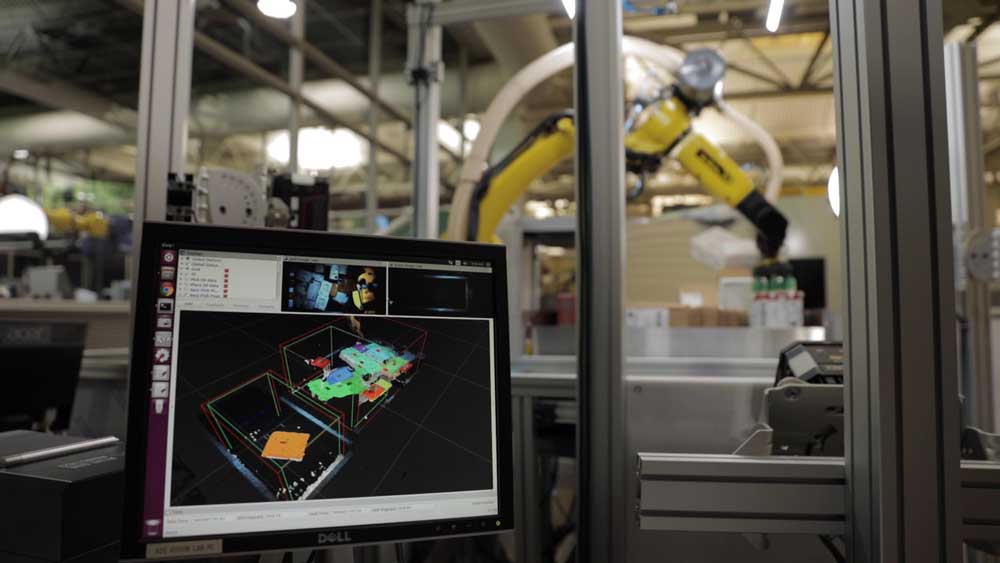

Industrial data and artificial intelligence are key drivers of automation in food packaging. The Industrial Internet of Things (IIoT) comprises a vast network of machines equipped with sensors, software, and other technologies.

Custom robotics systems utilizing AMRs and cobots form an integral part of this ecosystem. They facilitate comprehensive data collection across your entire manufacturing line and contribute to building a unified data architecture. This allows you to identify areas for optimization more effectively.

Consistency in Processes

Automation is pervasive in almost every industrial process, from battery assembly to vision system inspection to metrology. Consequently, food and beverage manufacturers can execute physical manufacturing and measurement tasks with unprecedented speed and accuracy.

Tasks that once required manual removal of parts for tracking can now be completed continuously and consistently through precise automation integration. This ensures a high level of process consistency throughout your operations.

Enhanced Safety in the Factory

Automation reduces the need for human labor, leading to a decreased risk of injuries. However, complete human replacement is not yet feasible. Recent trends indicate a growing emphasis on collaboration between robots and humans rather than complete substitution. By implementing AMRs or cobots, you can improve working conditions for your human workforce while maintaining safety standards.

Improved Ergonomics

Both AMRs and cobots excel in swiftly and efficiently moving physical products along the assembly line. These automated solutions can take on physically demanding tasks, offering relief to workers.

According to the Occupational Safety and Health Administration, shifting strenuous physical tasks from humans to robots plays a crucial role in reducing overall risk and injuries. By eliminating hazards through the replacement of human labor with machine labor, you can mitigate ergonomic risks.