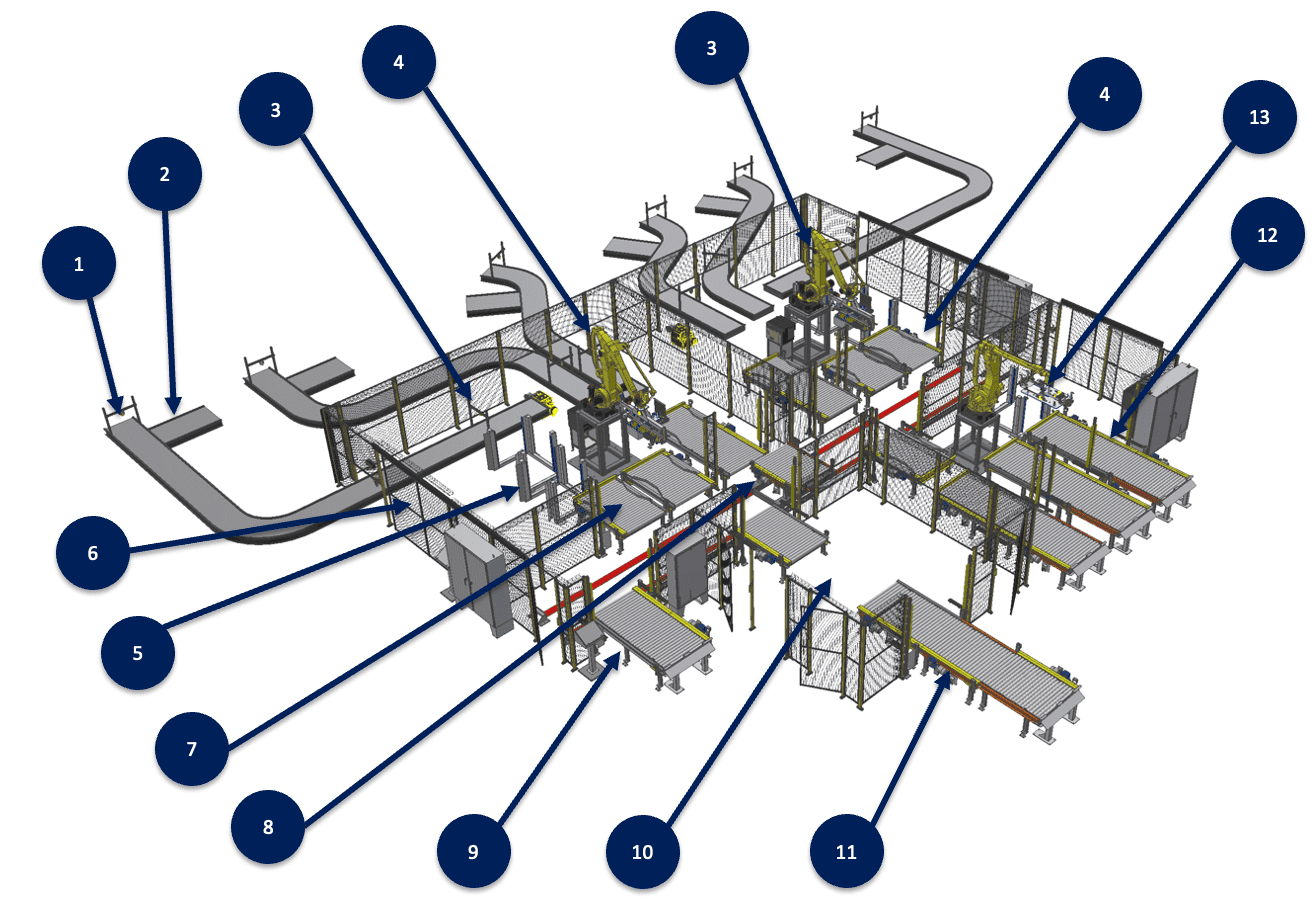

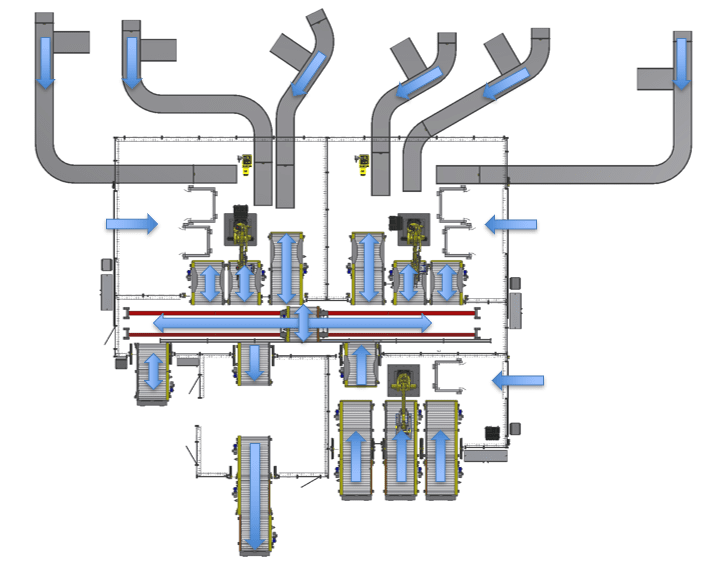

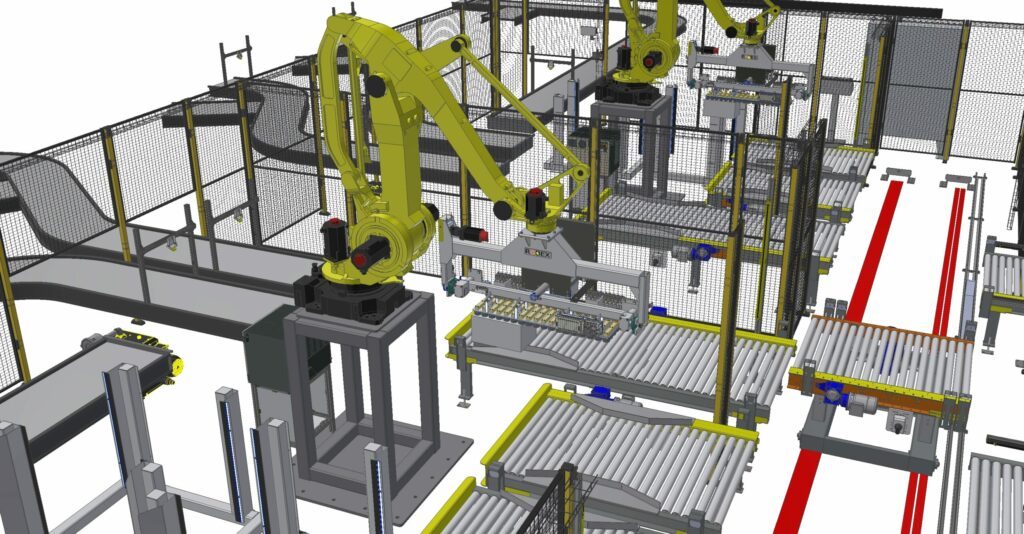

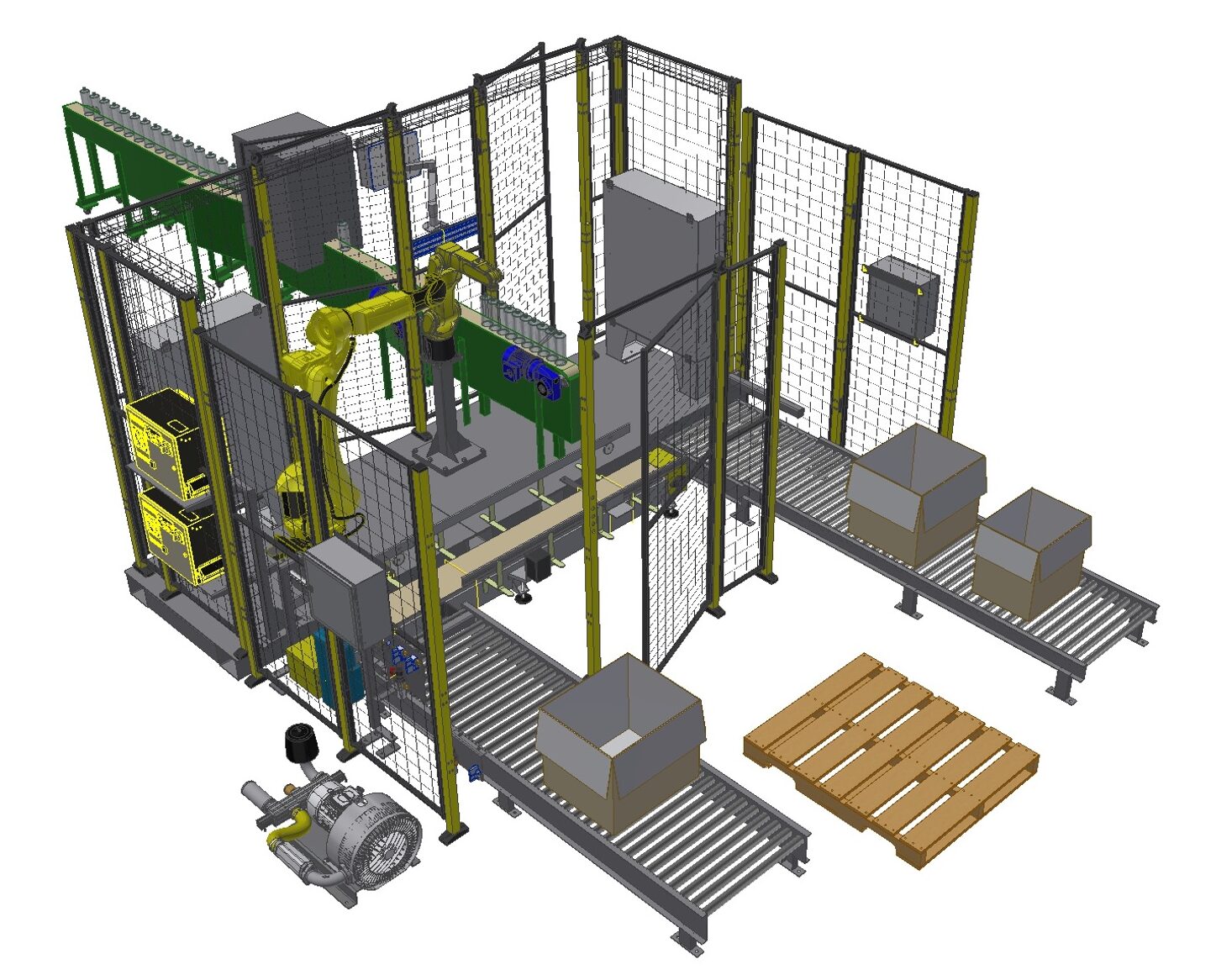

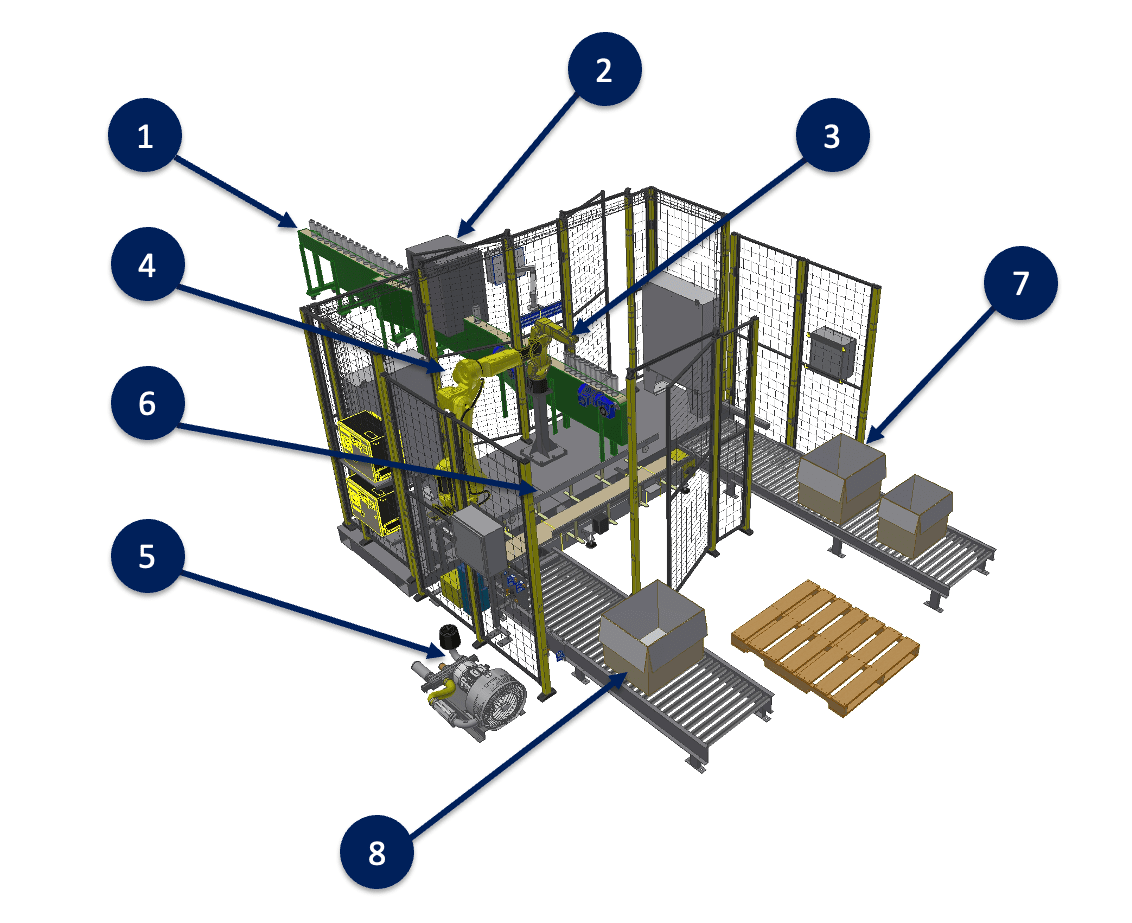

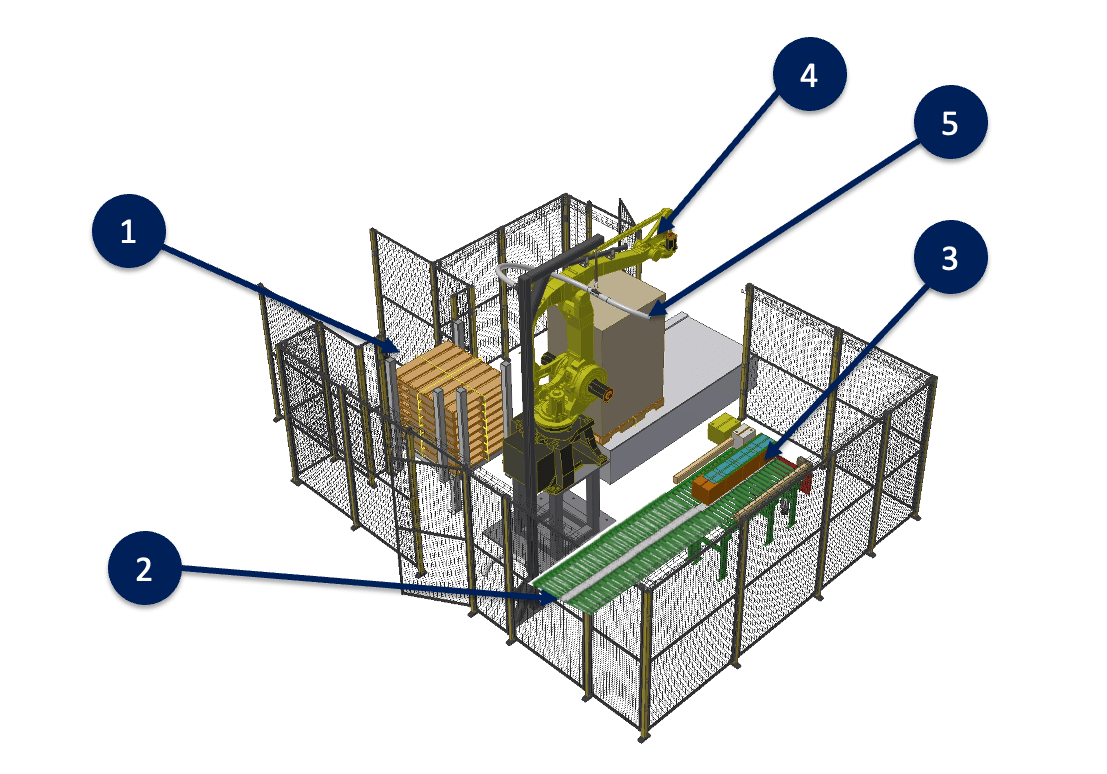

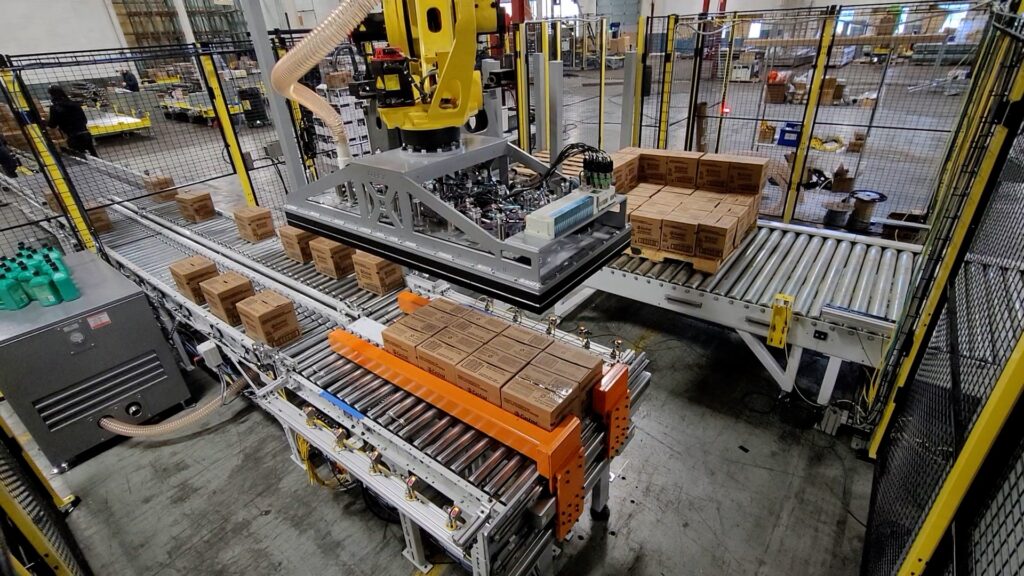

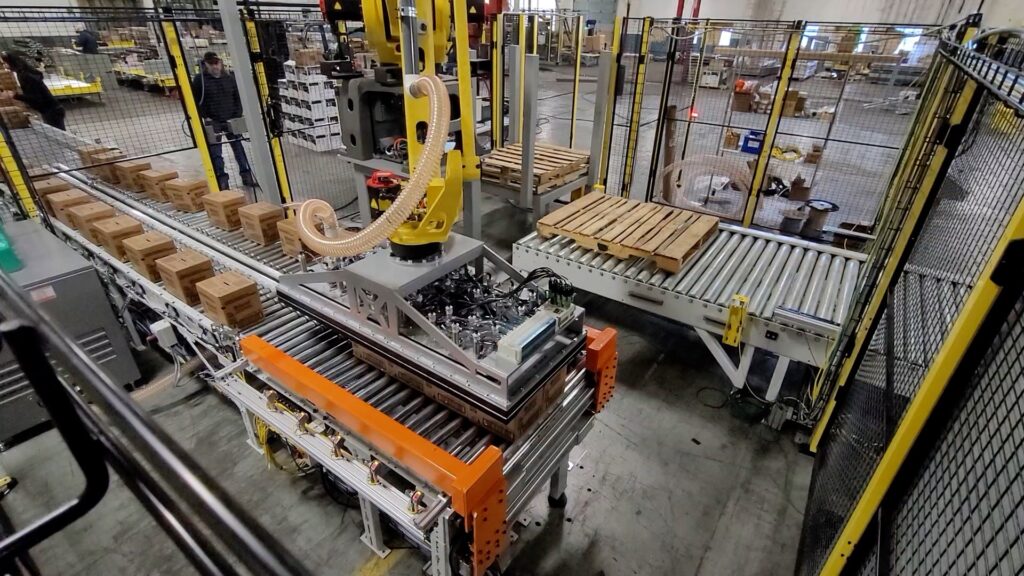

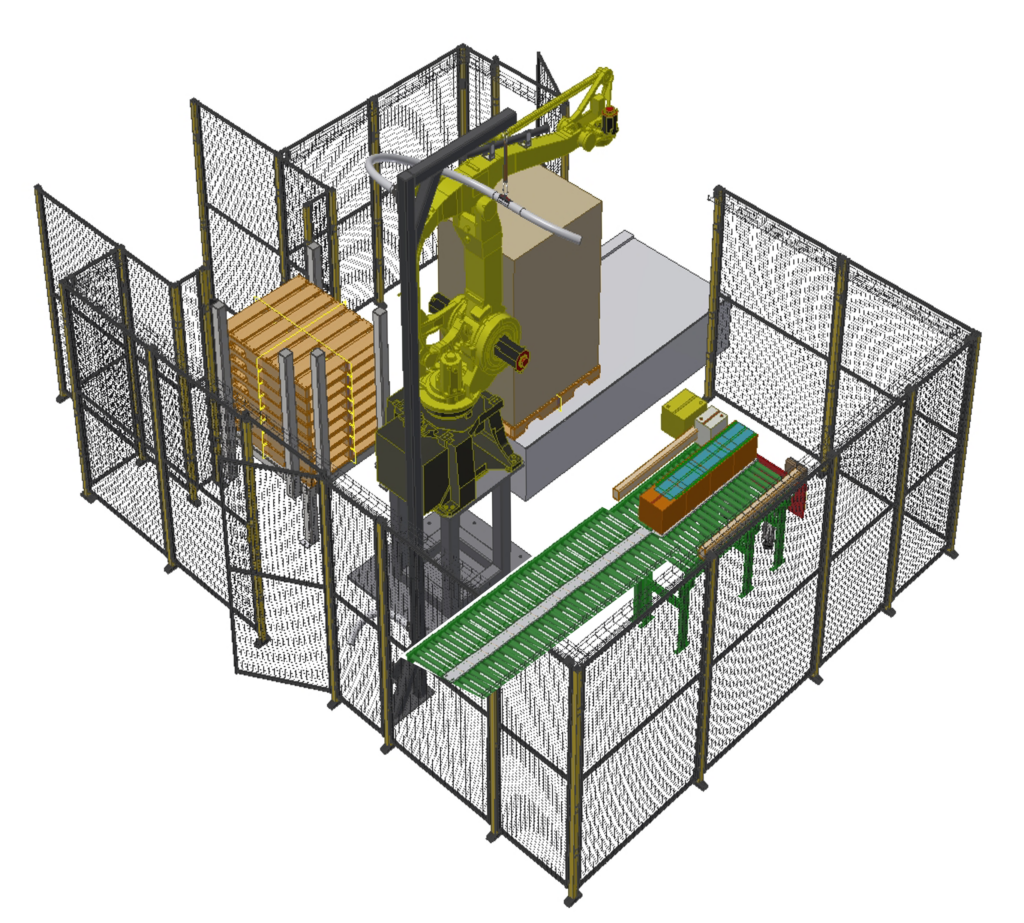

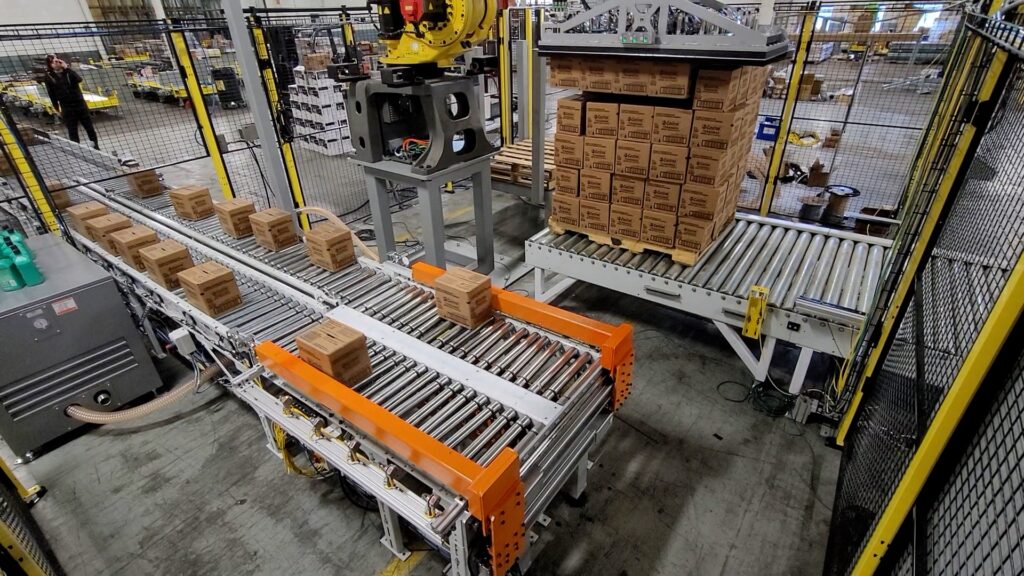

Real-World Pick, Pack, & Palletizing Systems

With RōBEX, businesses of all sizes can streamline processes and increase productivity. Take a look at the case studies below for more details about how we automate, inspect, and integrate systems. Specifically, see how you can optimize your pick and pack fulfillment operations with RōBEX!