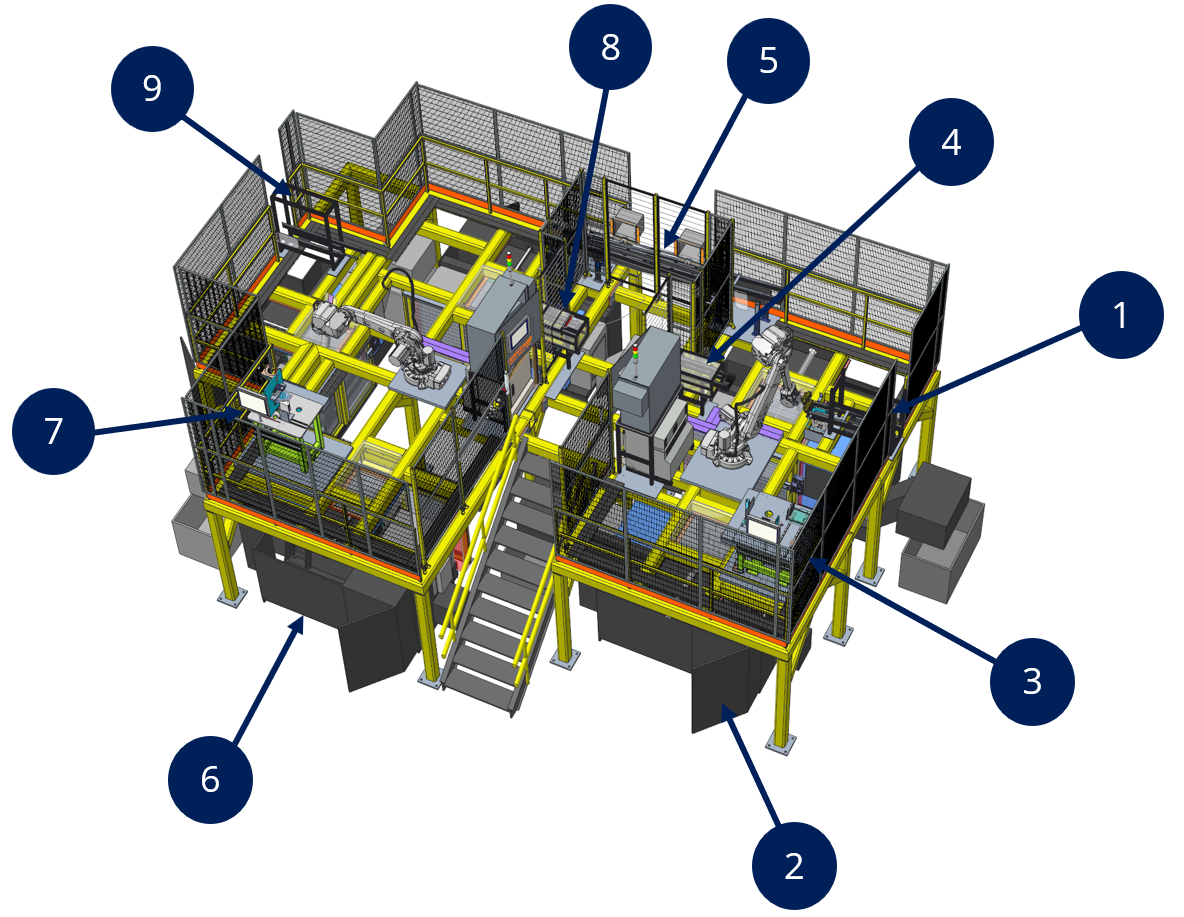

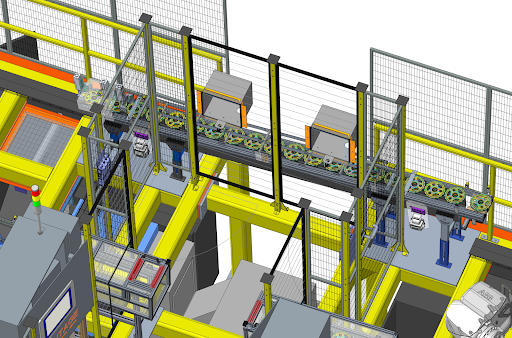

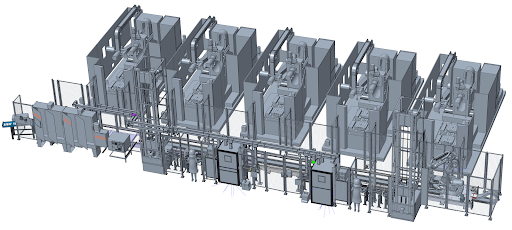

Real-World Material Handling Systems

RōBEX works with businesses of all sizes to find the most effective way to streamline processes and increase productivity. Read through the case studies below for more details about our approach to automation, inspection, and systems integration. Learn how RōBEX can help you optimize your material handling processes!