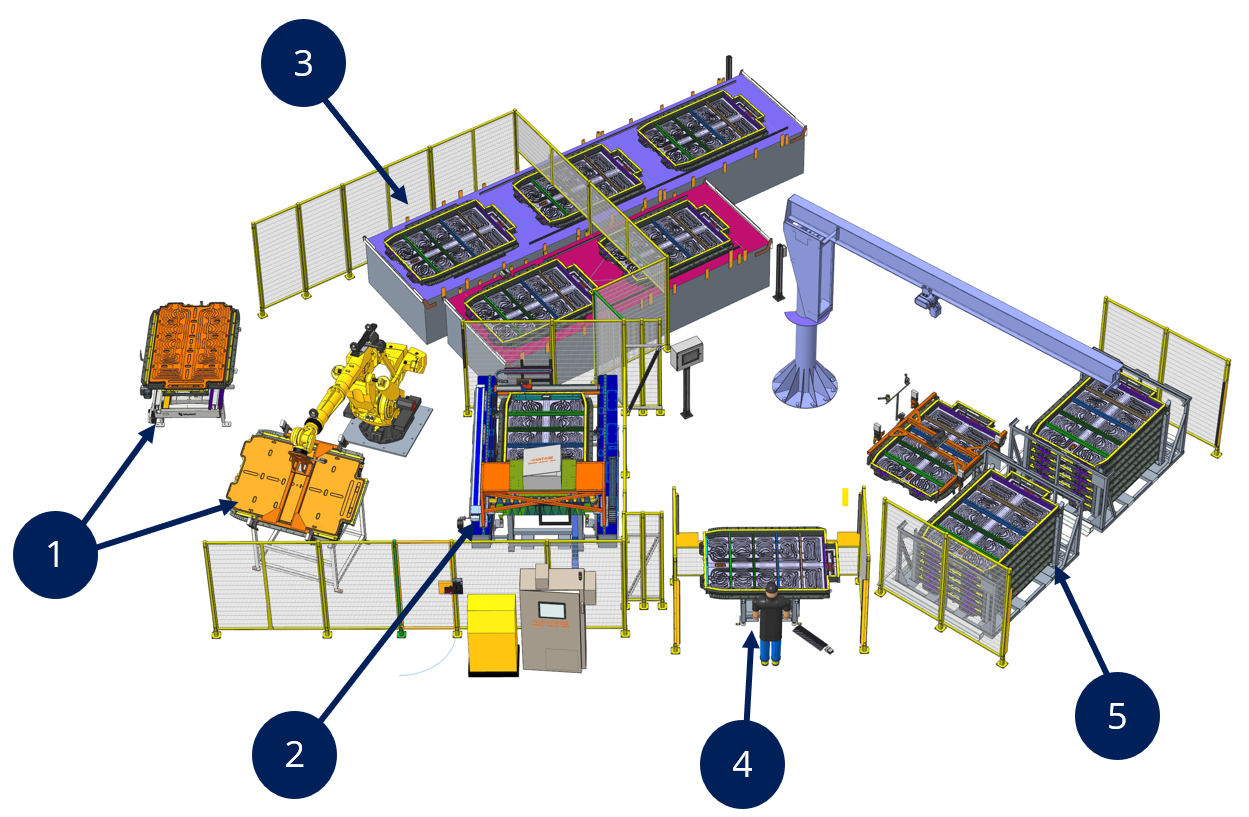

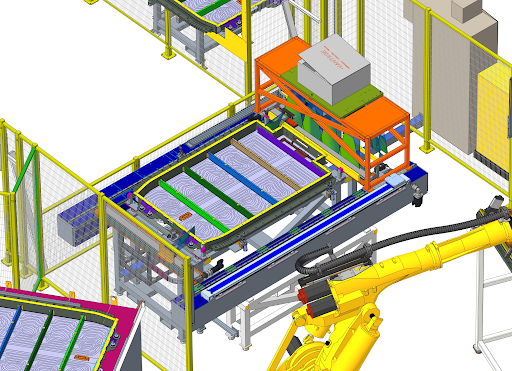

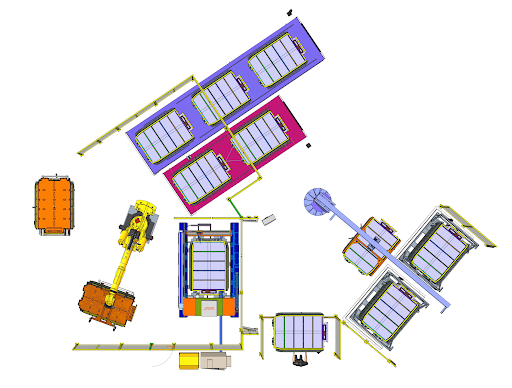

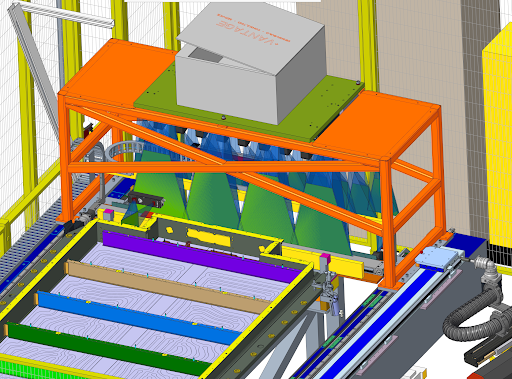

Providing Seamless Automation

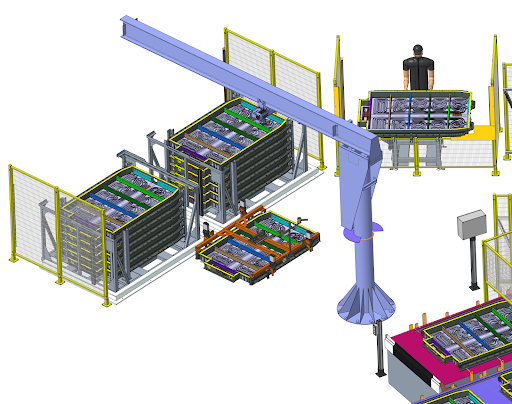

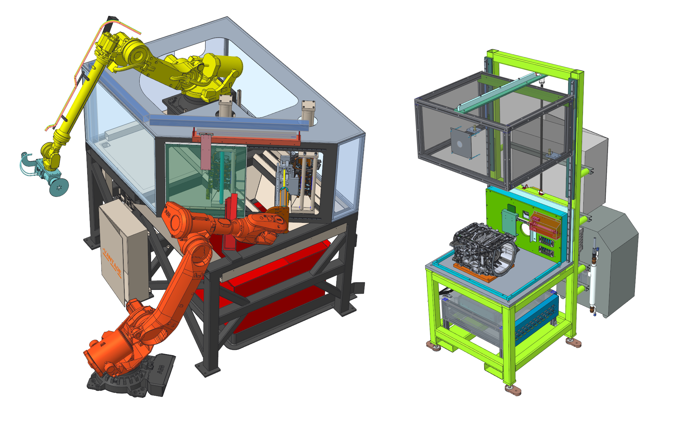

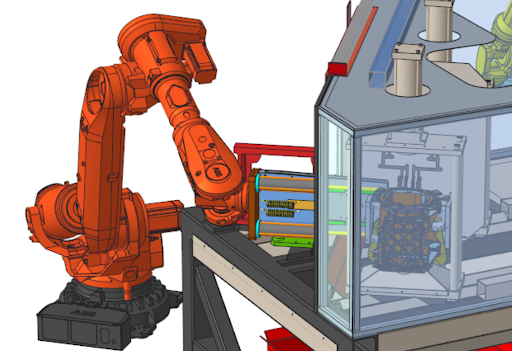

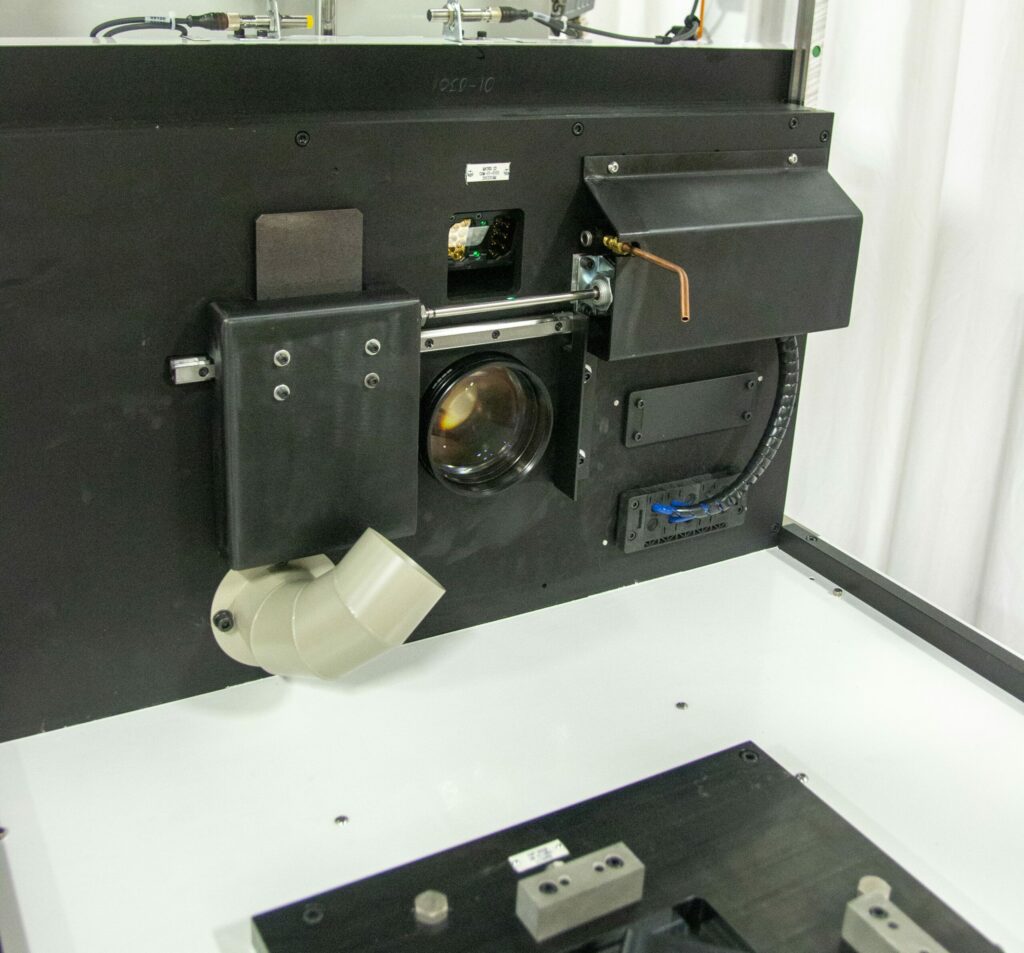

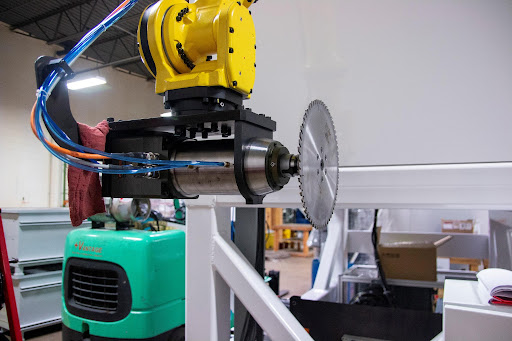

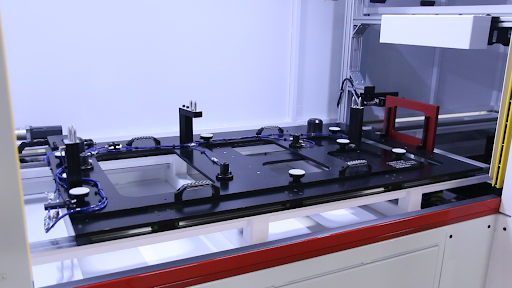

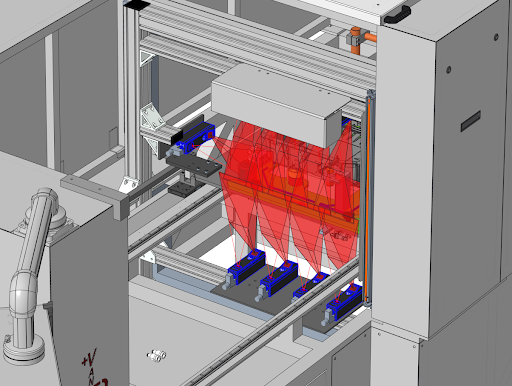

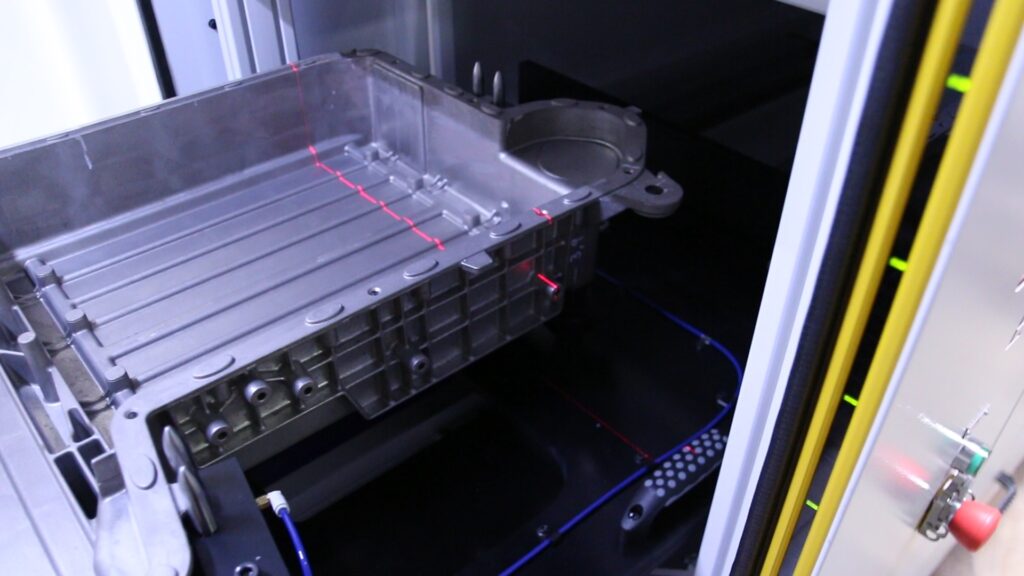

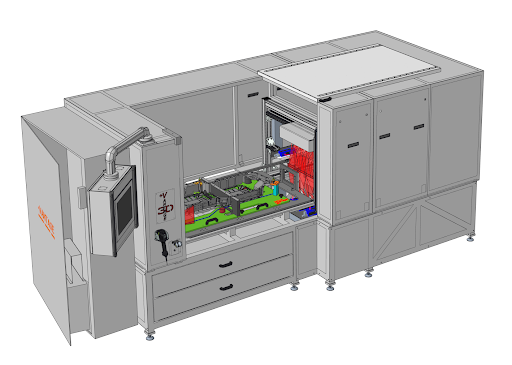

RōBEX has decades of experience in bringing automation solutions to the forefront of expanding industries. In these case studies, we show how automated degating, material handling, and inspection technologies empower electric vehicle OEMs to make the most of their production line.