3D & 2D Non-Contact Vision Inspection Systems

RōBEX offers powerful 2D and 3D vision systems for 100% inspection, assembly verification, and other advanced processes.

RōBEX offers powerful 2D and 3D vision systems for 100% inspection, assembly verification, and other advanced processes.

RōBEX offers a powerful line-up of non-contact inspection solutions, making 100% automation easily integrated into any process. Our turnkey units are optimized for manufacturing, providing a modular inspection process that can be tweaked as a process develops. We have the ability to incorporate state-of-the-art robotics and vision equipment into your automation needs to meet exacting specifications. With our in-house custom fabrication resources we are able to transform raw stock metal and technical components into highly finished pieces of equipment to help you achieve your process automation goals. Here is how we utilize advanced 2D and 3D vision inspection technology to create superior non-contact inspection automation.

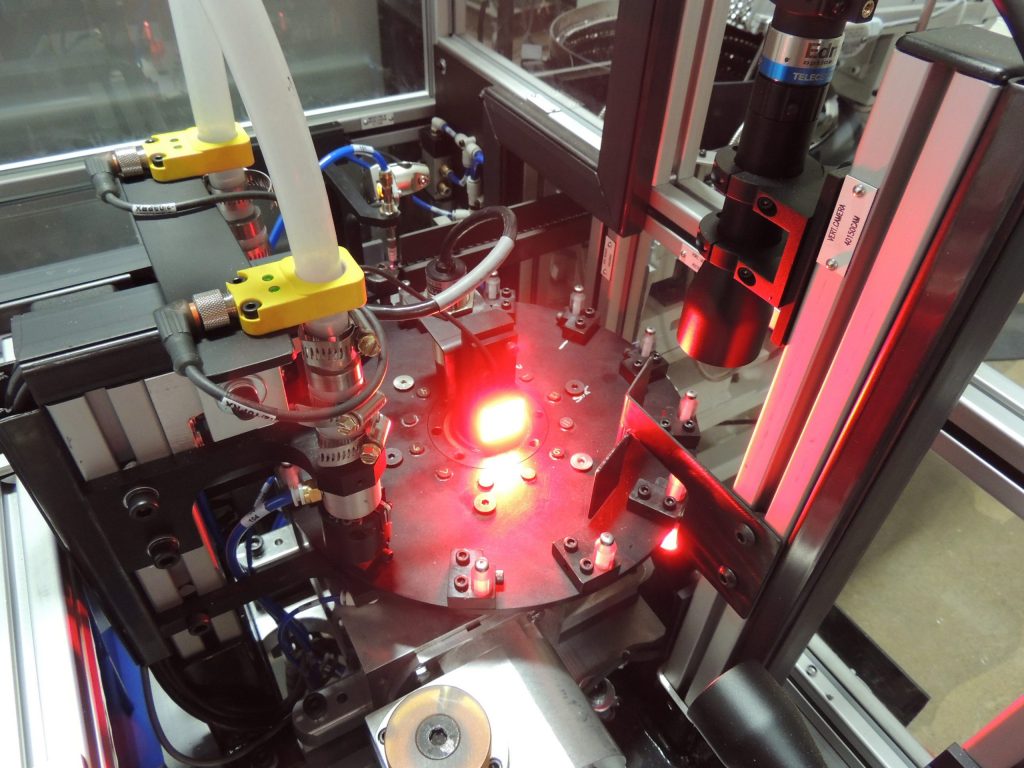

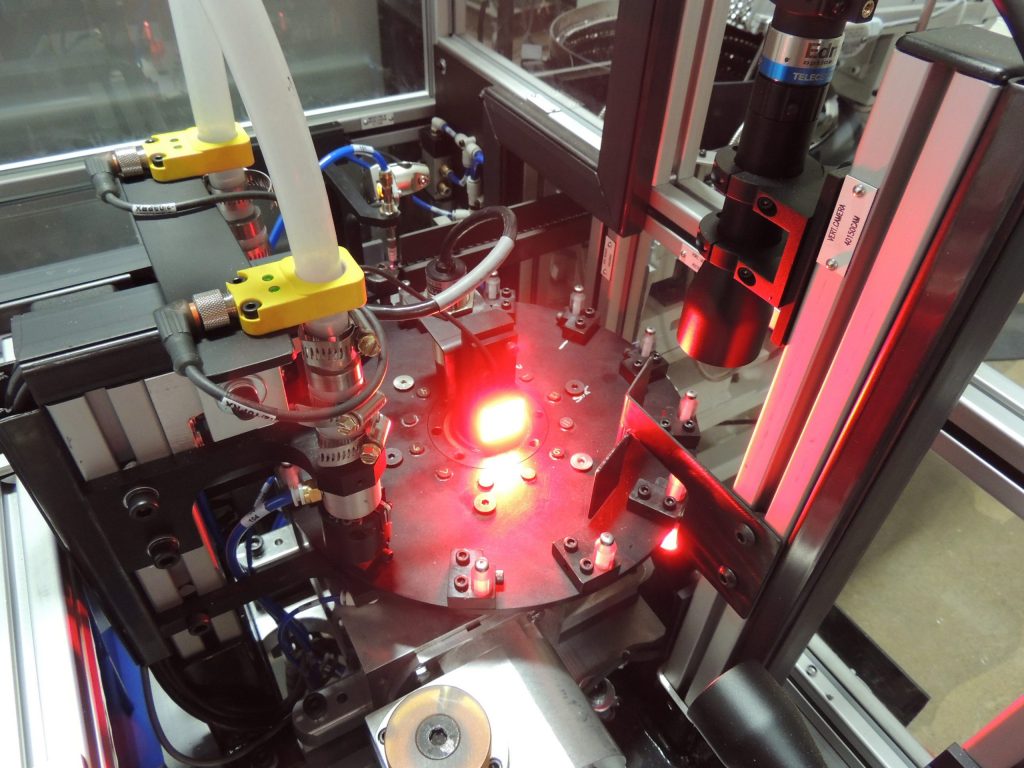

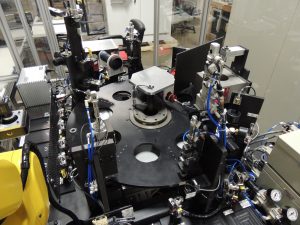

3D visual inspection offers flexible, easy-to-integrate technology for non-contact inspection. With a variety of different 3D systems at your disposal, everything from surface inspection to adhesive application to dimensional inspection drops seamlessly into your process. Additionally, a 3D automated visual inspection can be robot-mounted or fixed, providing versatility to an inspection system. Even better, at RōBEX, we maintain our own R&D vision lab to develop new applications, supporting you and your process for 100% inspection.

2D visual inspection offers simple inspection solutions for low and high-volume production applications. These systems are ideal for vision inspection of defects such as porosity, color verification, scratches or missed polish, or non-clean up. Integrating vision systems into your process offers 100% non-contact inspection through rapid-tracking machine vision.

2D visual inspection offers simple inspection solutions for low and high-volume production applications. These systems are ideal for vision inspection of defects such as porosity, color verification, scratches or missed polish, or non-clean up. Integrating vision systems into your process offers 100% non-contact inspection through rapid-tracking machine vision.

Vision systems are also vital for inspections that cannot be done by traditional gaging methodologies. This includes issues such as visual defects, which in the past have relied on subjective inspection by a human operator. Automated vision systems remove subjective analysis entirely, instead using AI (Artificial Intelligence) or programmed variables.

Altogether this allows for true 100% inspection of parts. The high-quality production data can also be used in process control—including Poka-Yoke inspection—to catch defects early. And as an added benefit, our RōBEX R&D vision lab develops new applications, supporting custom lensing and setups for specific process requirements.

NEED FURTHER INFORMATION OR

CONTACT US

automation@robex.us

+1.734.432.5055

8600 S Wilkinson Way, Perrysburg, OH 43551

Get in Touch

RōBEX

1745 Indian Wood Cr

Suite 210

Maumee, OH 43537

© 2024 RōBEX – Industrial Automation, Metrology and Manufacturing Systems Integration. All Rights Reserved