Eddy Current & Resonance Test Systems

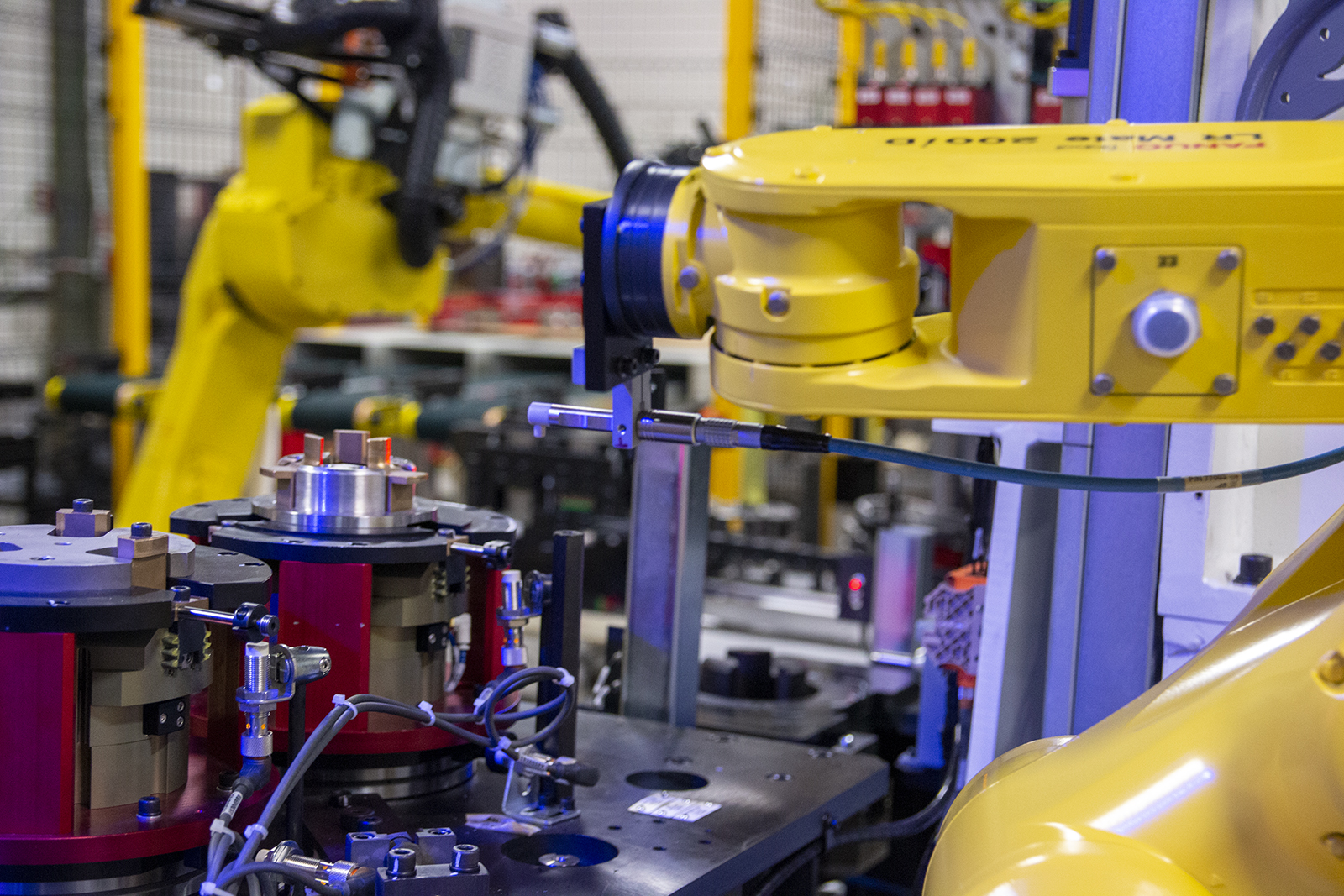

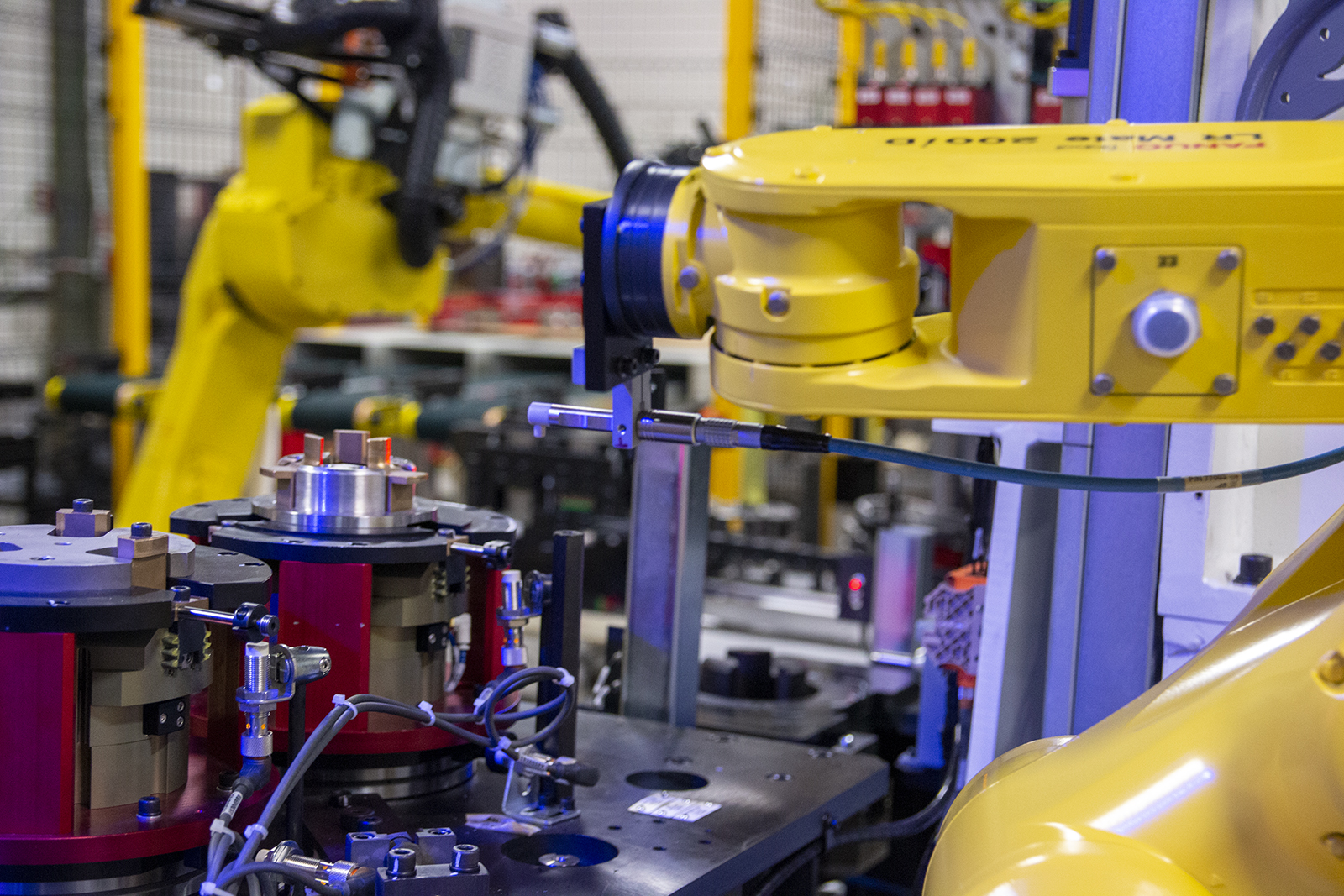

RōBEX utilizes eddy and resonance test systems to provide non-destructive inspection solutions for precision manufacturers.

RōBEX utilizes eddy and resonance test systems to provide non-destructive inspection solutions for precision manufacturers.

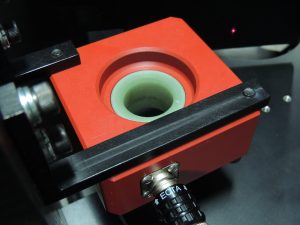

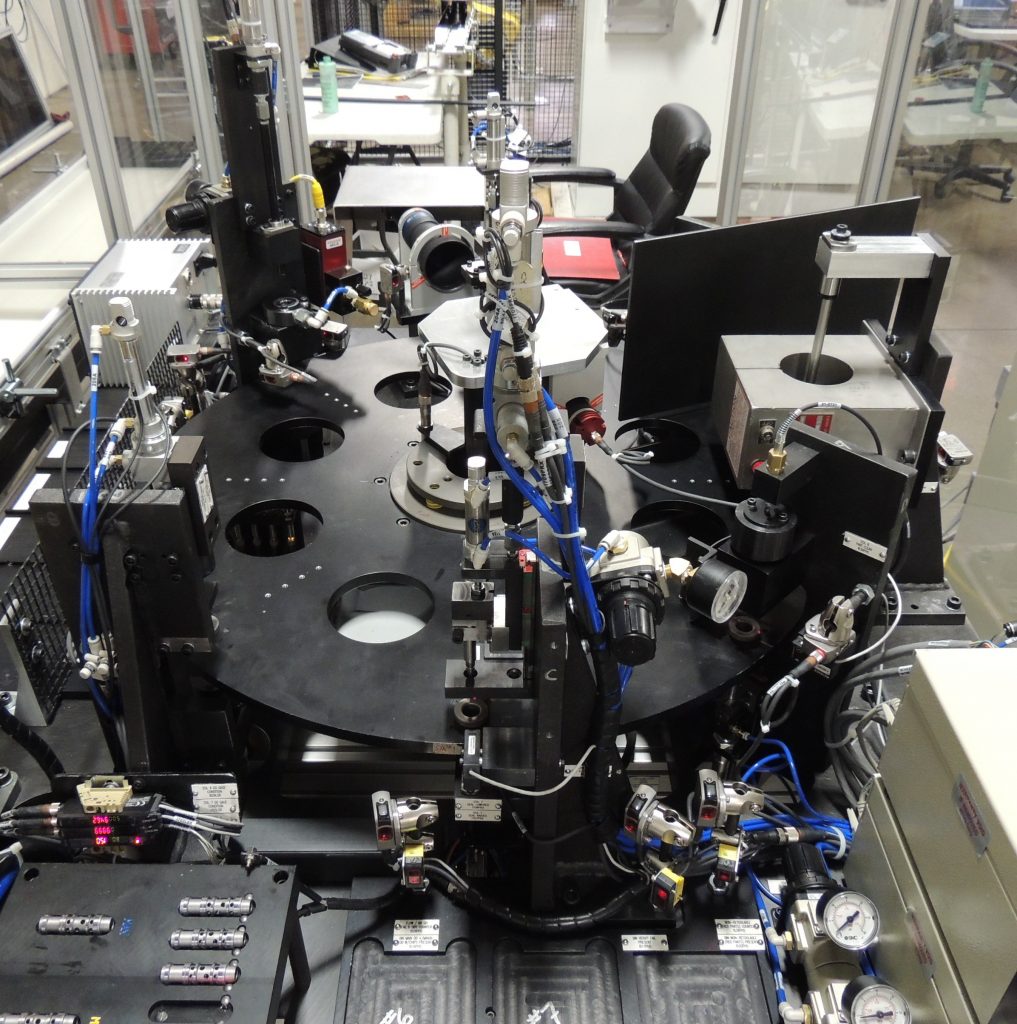

RōBEX offers several non-destructive test options for precision component inspection. We integrate specialized testing methods specific to the application including eddy current and resonance testing systems to give our clients the most effective and efficient system for their process. Here are some of the benefits and use cases of the two techniques:

RōBEX offers eddy current to offer powerful non-destructive testing (NDI) capabilities for part inspection. Eddy current testing uses electromagnetic induction to inspect metal components for cracking, non-conductive coating thickness, material conductivity, and heat treatment. Changes in electrical impedance indicate the presence of defects, allowing for rapid automated part sorting.

Resonance testing systems utilize the known resonance frequency of a given object to check for structural defects. By passing vibrational frequencies through your component at resonance, any deviation in response will alert you to the presence of defects. Together, these methods allow manufacturers to effectively automate inspection, increasing speed without sacrificing valuable components.

NEED FURTHER INFORMATION OR

CONTACT US

automation@robex.us

+1.734.432.5055

8600 S Wilkinson Way, Perrysburg, OH 43551

Get in Touch

RōBEX

1745 Indian Wood Cr

Suite 210

Maumee, OH 43537

© 2024 RōBEX – Industrial Automation, Metrology and Manufacturing Systems Integration. All Rights Reserved