Torquing Systems

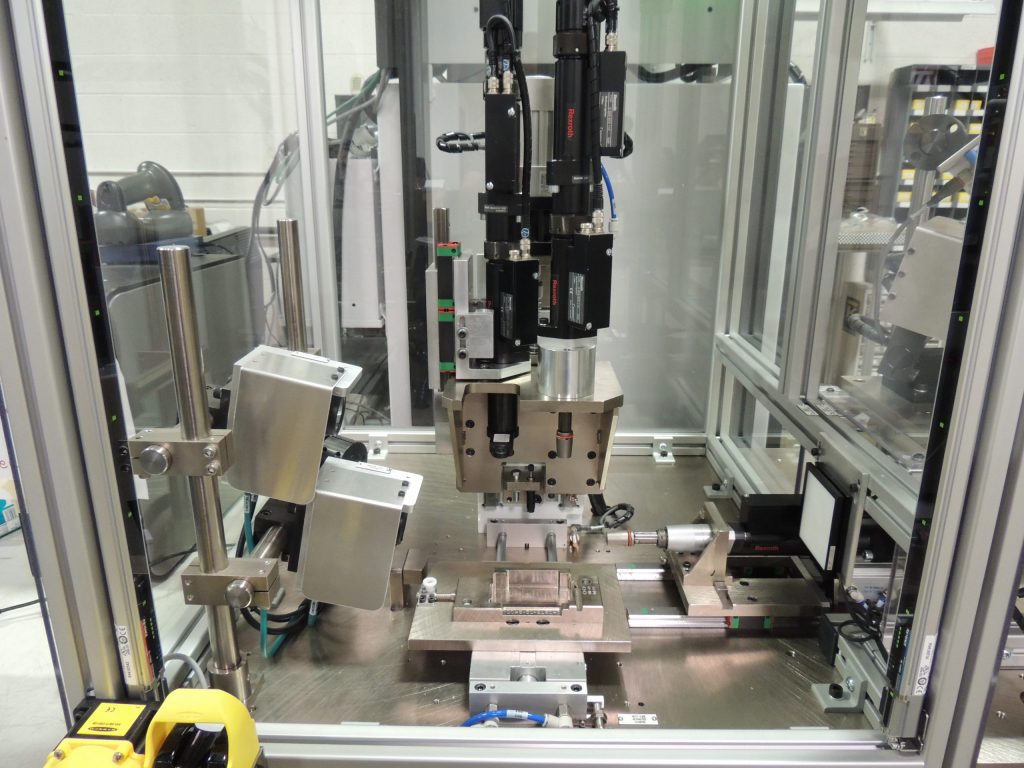

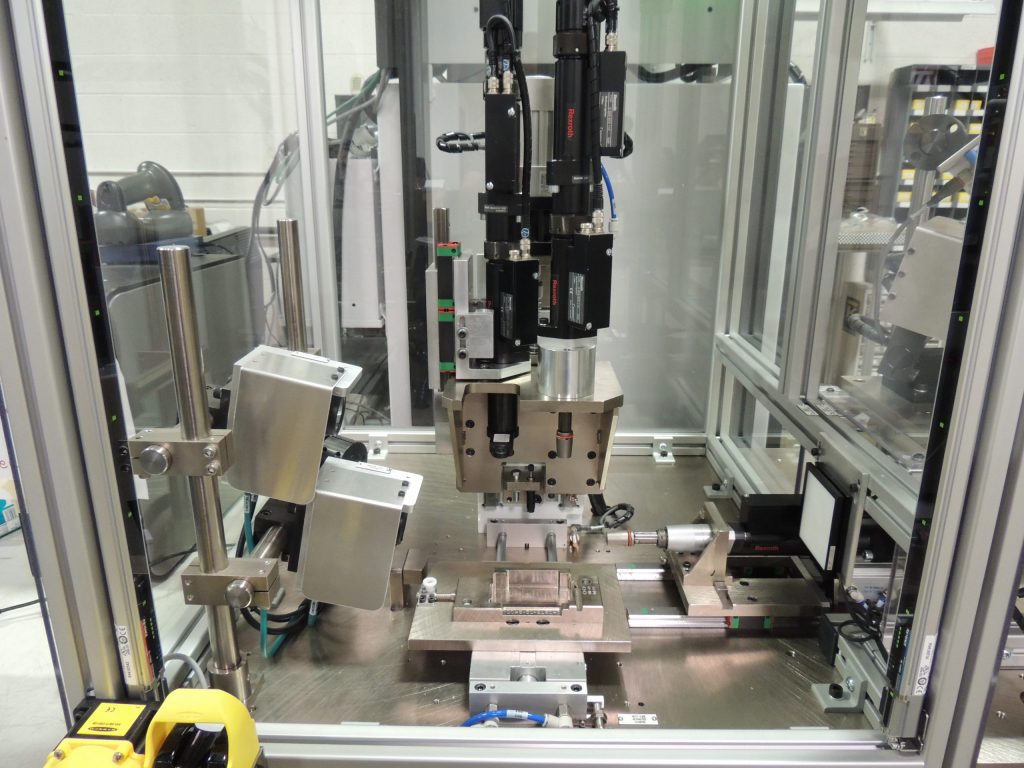

RōBEX automated torquing systems are engineered with the detail and versatility to fit the needs of any application.

RōBEX automated torquing systems are engineered with the detail and versatility to fit the needs of any application.

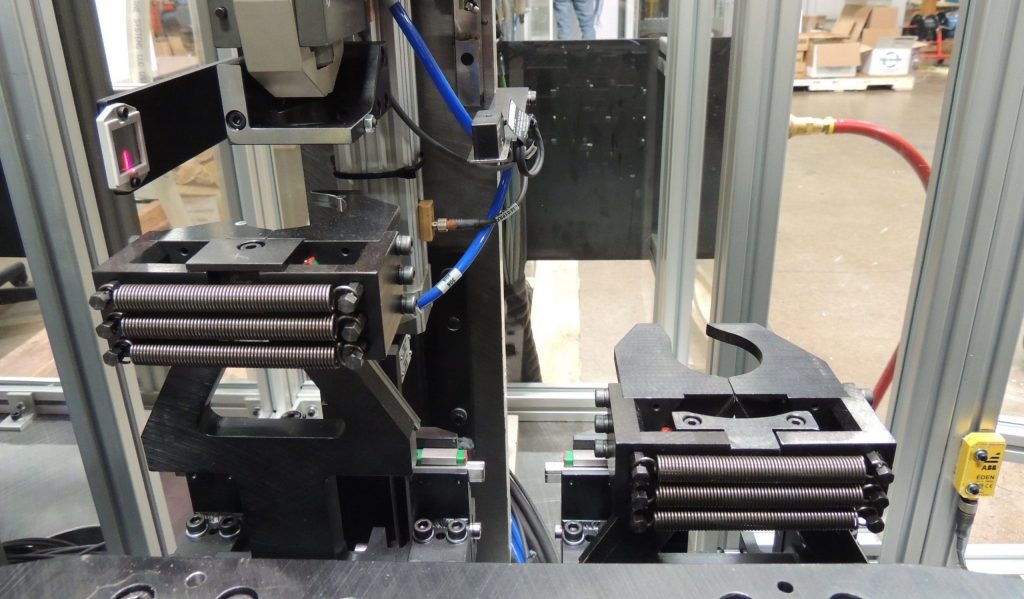

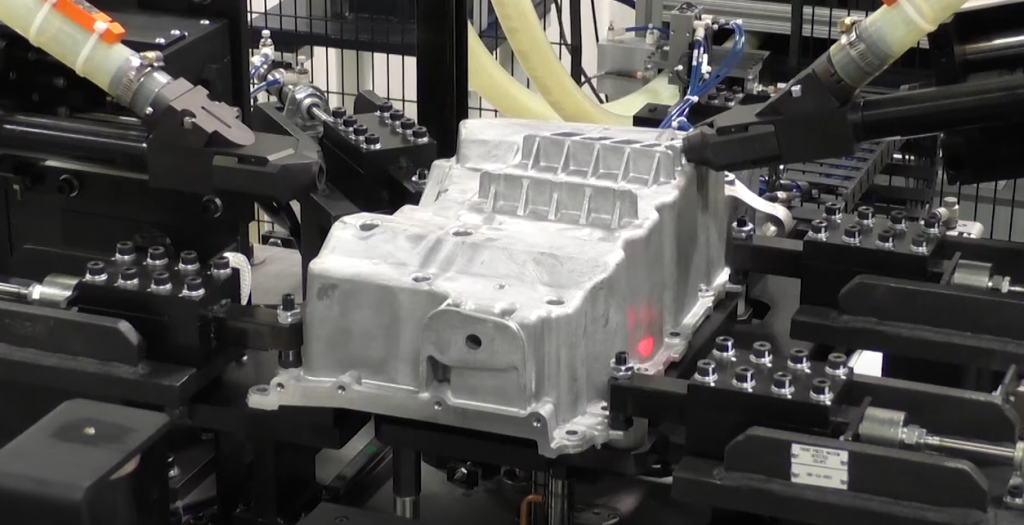

Proper torque is vital when creating a safe vehicle, and car manufacturers have dozens of different demands, both in size and precision. From high-torque, wide-tolerance lug nuts to the precision of attaching an air compressor to an engine block, torque systems have historically been left to workers due to the delicacy required and the high cost of failure. But, new advancements allow assembly equipment manufacturers to implement carefully calibrated torque systems into their process. These systems are ideal for joining sub-assemblies, and integrate seamlessly with your assembly line.

RōBEX automated assembly equipment has integrated torque and angle monitoring, with fully customizable torque sequences protecting against dangerous errors that could result in a recall. This includes customizable torque sequences for an even preload distribution. Also available is post-torque inspection, which acts as a final safeguard against sub-par components winding up in a vehicle. These systems can be set up as either blow-fed or track-fed processes, depending on the needs of the application.

NEED FURTHER INFORMATION OR

CONTACT US

automation@robex.us

+1.734.432.5055

8600 S Wilkinson Way, Perrysburg, OH 43551

Get in Touch

RōBEX

1745 Indian Wood Cr

Suite 210

Maumee, OH 43537

© 2024 RōBEX – Industrial Automation, Metrology and Manufacturing Systems Integration. All Rights Reserved