A New Era of CNC Machinery Automation

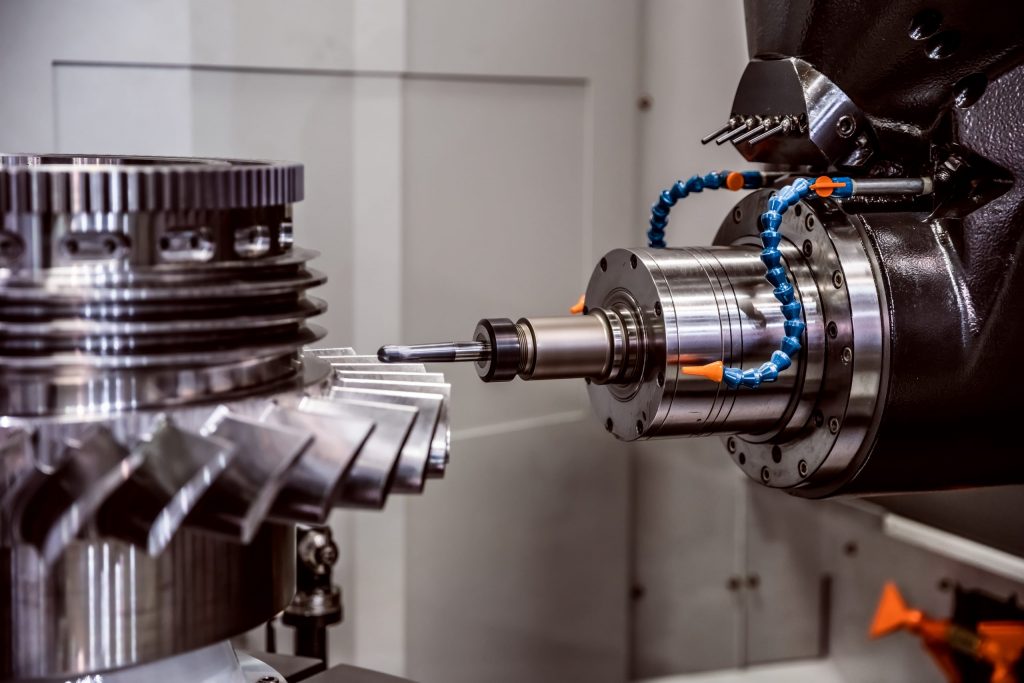

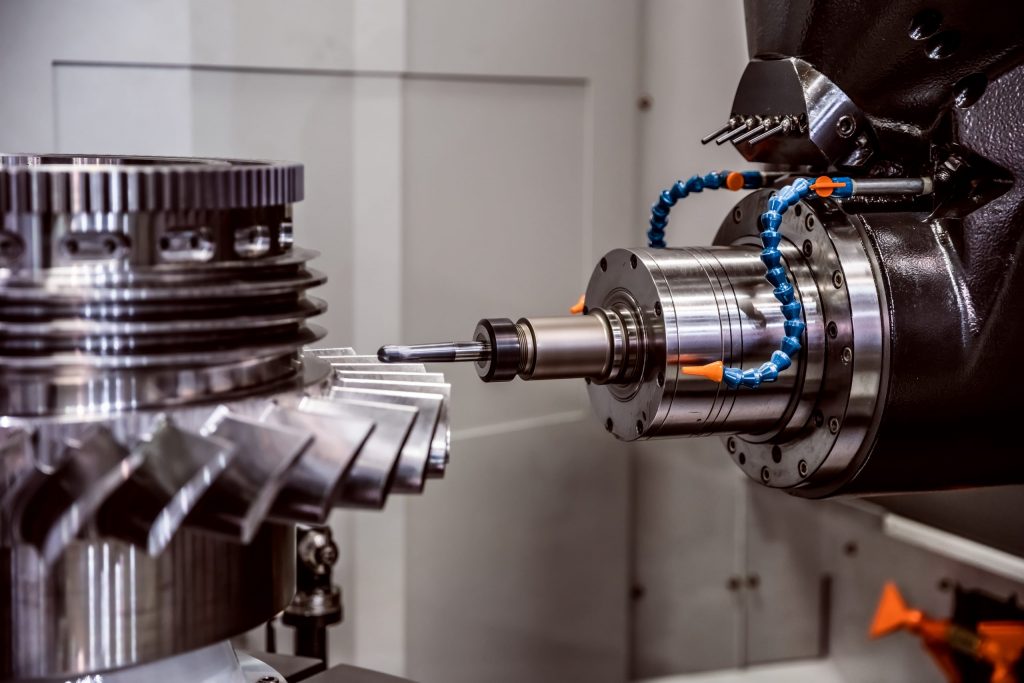

Computer Numerical Control (CNC) has been a staple of manufacturing since the 50s, changing what is possible for high-volume production of precision parts. However, a human operator has always been part of the equation. This puts hard limits on the speed a production line can attain.

Computer Numerical Control (CNC) has been a staple of manufacturing since the 50s, changing what is possible for high-volume production of precision parts. However, a human operator has always been part of the equation. This puts hard limits on the speed a production line can attain.

Manual piece insertion, removal, and inspection means a slower process with minimal process control capabilities. Today, fully integrated systems offer 100% turnkey CNC machine automation solutions, providing massive benefits to manufacturers.

Why Modern CNC Automation Needs Machine Part Tending

To create a truly integrated system, a CNC automation process needs to be able to eliminate the operator. With no sick days, breaks, or human error, industries can reach their full productive potential, operating 24/7 in a lights out capacity. A fully independent system also allows for space efficiency and real-time process control, potentially leading to tens of thousands of dollars saved in facility costs and reduced downtime.

To achieve this, manufacturing lines require a comprehensive support system for CNC machinery, conveying incoming parts and testing outgoing parts. As your all-in-one CNC system integrator, Vantage accomplishes this through our in-house approach to integrating tooling cells. This doesn’t just include the CNC itself, but part tending, tool compensation and automated inspection systems.

3 Benefits of CNC Automation

Ideal for High Volume Applications

Ideal for High Volume Applications

Automatic CNC processes can execute a complex series of tasks, condensing staggered, asynchronous procedures into a seamless line. This reduces the processing time on an individual piece, accelerating throughput. Handling systems also require minimal oversight and maintenance to perform repeated tasks. This reliability allows automated CNC cells to run 24/7 with confidence and flawless execution. For all intents and purposes, this is the same as lights-out manufacturing—a long-term goal for the industry.

Precision Performance at Every Step

The precision of an automated part handling system perfectly sets up an unfinished piece for cutting every time, meaning fewer defective parts. On the other end, visual inspection systems and automated gauges can provide instantaneous detection on parts that aren’t up to spec. Automated part handling can also include laser and part marking equipment, integrating FIS and traceability smoothly into the production line.

Safe, Easy Oversight for Operators

Finally, the comprehensive process control feedback from integrated gauge systems allows manufacturers to track automation from afar, minimizing the number of employees on the factory floor. This minimization of operator interaction also results in a safer workplace.

For manufacturing units that work with corrosive or abrasive substances or require high temperatures conditions, CNC automation creates a vastly superior environment for employees. Statistical Process Control (SPC) and real time data collection has long been a hallmark of the Vantage approach to automation, and it is an especially powerful tool when applied to CNC robotics.

How to Successfully Automate CNCs

Integrated Manufacturing Cells

Cellular manufacturing refers to a theory of manufacturing concerned with maximizing speed and minimizing waste while creating similar items. It functions by dividing up the production into multiple smaller tasks, each completed by progressive “cells” in an assembly line setup. This system is ideal for automation, as there is immense flexibility in how the cells relate to each other.

Automation can be fully automatic at each stage, with custom solutions in accordance with the needs of the manufacturer. +Vantage has the experience and technical mastery to lead your business through a successful integration, utilizing our comprehensive product line to provide 100% automation.

Utilizing Turnkey Solutions

Building a custom CNC automation system on your own from the ground up is a massive expenditure that may take many years to see an ROI. Fortunately, turnkey automation solutions make full automation integration a seamless process, especially with our experience in projects of this exact nature. Introducing ready-made manufacturing cells, complete with machine tending, inspection, and tool compensation into an existing process minimizes costs while offering the fantastic benefits of speed and up-to-the-second oversight.

Building a custom CNC automation system on your own from the ground up is a massive expenditure that may take many years to see an ROI. Fortunately, turnkey automation solutions make full automation integration a seamless process, especially with our experience in projects of this exact nature. Introducing ready-made manufacturing cells, complete with machine tending, inspection, and tool compensation into an existing process minimizes costs while offering the fantastic benefits of speed and up-to-the-second oversight.

Turnkey systems providers like +Vantage offer comprehensive solutions for CNC manufacturing cells, from conveying to process control. +Vantage even includes integration, maintenance support and project services, ensuring a seamless automation process for any application well after the point of sale.

Quality Control

One major aspect of automation is the ability for manufacturers to implement inspection and real time process control into their line. This means quality checks for every piece integrated into the line, completed by an accompanying, automated inspection cell and passed from CNC to inspection cell by a machine loading robot. At +Vantage, we build automatic gauges into our manufacturing cells, allowing for 100% inspection of pieces.

The potential of on-machine measurement doesn’t end there either. Recent developments in self-learning algorithms enable manufacturing systems to learn from previous data, eliminating errors and consistently producing quality products.

Tool Compensation

Over tens of thousands of cycles, the cutting head on a CNC machine naturally wears down. If left unaddressed, this can result in waste, disappointed customers, and significant downtime. Fortunately, integrated metrology and CNC automation technology once again provide powerful solutions. On +Vantage machines, our RTGC software passes tool compensation data back to the CNC, increasing uptime, facilitating predictive maintenance, and providing an accurate picture of tool condition.

Automate With Us!

Are you ready to revolutionize your manufacturing process? To learn about the detailed +Vantage integration process, and the vast array of CNC machine automation services we offer, download our brochures!

To discuss how our systems can benefit your custom process, contact us to speak with an engineering design consultant today!

Computer Numerical Control (CNC) has

Computer Numerical Control (CNC) has  Ideal for High Volume Applications

Ideal for High Volume Applications Building a custom CNC automation system on your own from the ground up is a massive expenditure that may take many years to see an ROI. Fortunately, turnkey automation solutions make full automation integration a seamless process, especially with our experience in projects of this exact nature. Introducing ready-made manufacturing cells, complete with machine tending, inspection, and tool compensation into an existing process minimizes costs while offering the fantastic benefits of speed and up-to-the-second oversight.

Building a custom CNC automation system on your own from the ground up is a massive expenditure that may take many years to see an ROI. Fortunately, turnkey automation solutions make full automation integration a seamless process, especially with our experience in projects of this exact nature. Introducing ready-made manufacturing cells, complete with machine tending, inspection, and tool compensation into an existing process minimizes costs while offering the fantastic benefits of speed and up-to-the-second oversight.