+Vantage delivers turnkey solutions for every stage of your automation, manufacturing and inspection stages. Today we want to focus on vision systems, one of the most powerful tools at your disposal.

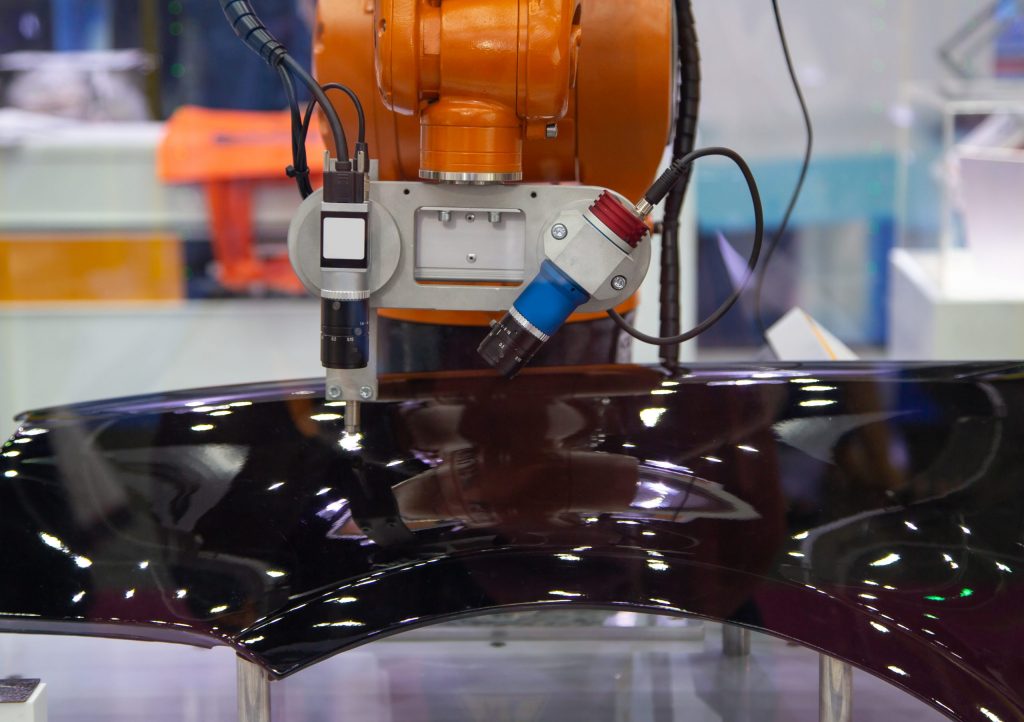

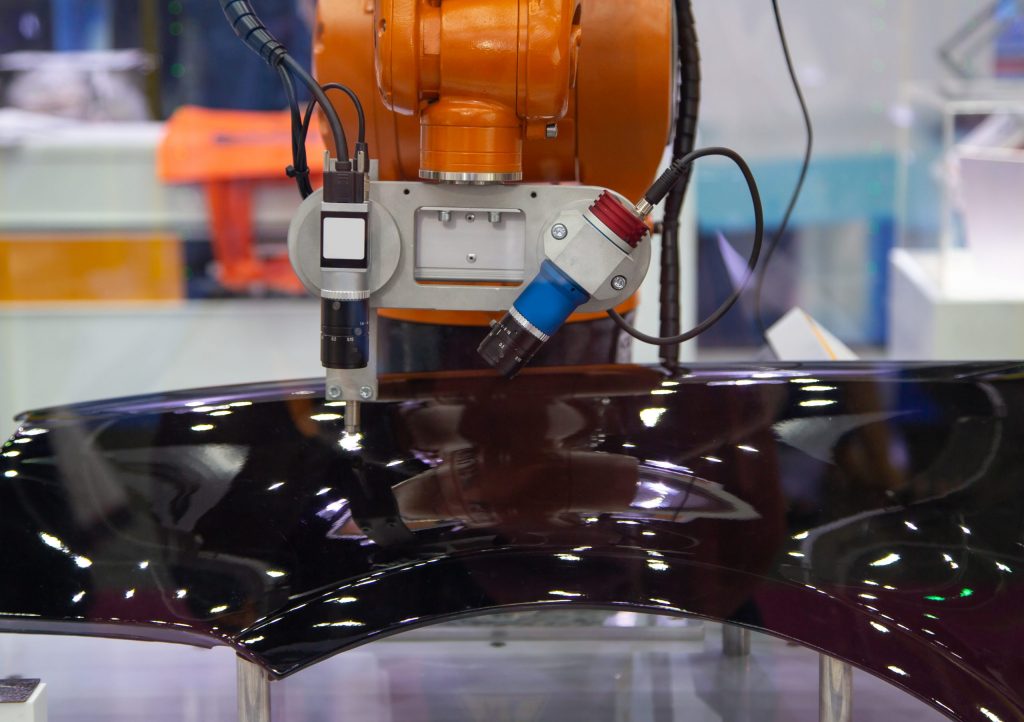

Vision systems may be seamlessly integrated into your manufacturing process, automatically accepting components from a tooling cell, providing a go/no go signal, and taking in measurement data, then moving the part along to the next step in the process. Vision inspection systems come in many forms, both for 2D and 3D inspection.

Types of Vision Systems

Vision systems generally break down into 2D and 3D varieties. As their name would suggest, 3D sensors use lasers or predefined patterns to generate a digital recreation of the part in question, while 2D systems more commonly use image recognition algorithms to identify a part.

3D Vision Systems

This type of vision system generally comes in two varieties: laser line profilers and 3D structured lighting. Laser line profilers, like those from our partner Keyence, use the displacement of a laser sheet off the surface of a part to generate height data, and in turn reconstruct the object. Laser profilers aren’t necessarily slow either, as Keyence’s LJ-V7000 series has a sampling rate of up to 64KHz for in-situ measurements.

3D structured lighting works differently, by projecting a pattern onto an object. Multiple cameras, or a single stereoscopic camera observe the distortion in the pattern, and algorithmically reconstruct the object. 3D structured lighting is highly precise, and features resolution on the order of a fraction of a micrometer.

2D Vision Systems

2D systems, while lacking the complete reconstructive capabilities of their 3D counterparts, offer their own set of unique benefits to an inspection stage. 2D vision systems come in many varieties, often using deep learning algorithms to identify part compliance against a master digital file, checking dimensionality and surface finishing to produce their go/no go signal.

These systems may also utilize telecentric lenses, which combat the distortion of light traveling through a refracting lens, which fundamentally changes the dimensions of an image. Telecentric lenses only allow light through which enters normal to the plane of the object. Thus, the received data retains 1:1 dimensionality of the planar surface being inspected.

Benefits and Applications

Geometric Compliance

Both 3D and 2D vision systems allow you to take in a scan or image of a part and compare it against a master file, giving you the ability to accurately determine how far your production components have drifted from your digital master, and whether you meet tolerances. 3D systems may allow you to check the entire component, while 2D systems are limited to planar measurements.

Surface Finishing

2D vision systems can use their built-in image and pattern recognition to identify gaps in surface finishing and painting. This saves you valuable time, which would otherwise need to be spent by a human operator examining the component.

Defect Identification

2D systems are always highly adept at using image processing software, built into the cameras themselves to identify defects in components. Image enhancement software, through the application of machine learning and intelligent filters, will extract particles and surface flaws from an otherwise difficult to discern image, then tag these parts for further inspection or remanufacture.

Speed

For inspection systems built into high-volume manufacturing lines, speed is of the essence. Modern vision systems can operate at speeds in excess of 200 frames/second, and up to 400 individual inspections per second, ensuring your inspection step is never the bottleneck in your process.

Industrial Partners

+Vantage is proud to be a partner and system integrator for the following vision system OEMs:

Contact Us Today

3D and 2D vision systems are integral to virtually every industry which requires speed, precision, and adherence to tolerance in their manufacturing process. If you want to learn more about our capabilities or already have a project in mind, please reach out to us, and our dedicated engineering team will get in touch!