+Vantage is always dedicated to providing you with the latest in automation, assembly, inspection and integration technology, so today we’d like to focus on one of our most valued industry partners, LMI Technologies. We work hand in hand with LMI to provide integrated inspection systems to the automotive manufacturing industry, and we hope you’ll see how this partnership ultimately benefits you, our clients.

Who is LMI Technologies?

LMI Technologies was founded in 1998 to develop 3D smart sensor technology. Their flagship Gocator and FocalSpec product lines offer a massive suite of tools to achieve 100% inspection, even on curved, reflective, and transparent surfaces. With their expertise in integrated inspection technology, they were a natural fit for us, given their extensive investment in smart factory solutions.

How Do LMI Products Benefit You?

Automotive manufacturers are rapidly expanding into the growing electric vehicle marketplace. To facilitate this, 3D automotive inspection steps are more important than ever. Both +Vantage and LMI offer dedicated technologies for EV OEMs. Electric vehicles require entirely new types of inspections, mainly centered around their battery cells. Cells must be properly bonded, reinforced, mounted, and sealed. Each of these steps requires both contact and non-contact inspection technologies to ensure batteries are road safe.

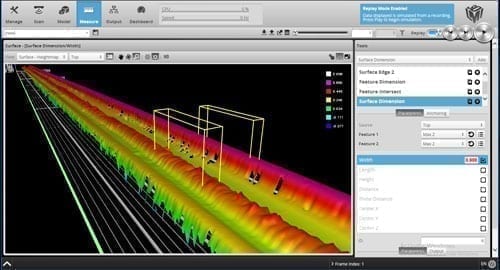

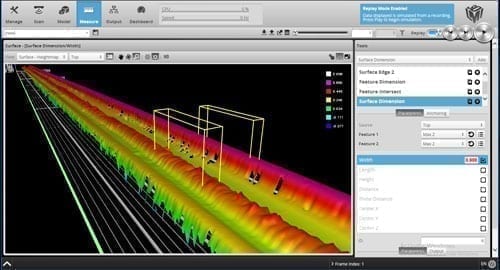

LMI has specifically developed an entire new line of sensors for electronics inspections, which we’ve integrated into our industry leading inspection cells. For instance, LMI’s glue bead inspection system—built on a Gocator laser line profiler—gives you access to a surface tracking tool to evaluate width, height, offset and continuity measurements of the glue application. This is only possible thanks to the 3D capabilities of the Gocator system.

The sensor can then feed statistical data into your statistical process control (SPC) tool of choice. This allows for real-time tracking of your production process, identifying trends through 100% inspection, and allowing for critical fixes and maintenance before it’s too late.

Case Study: 3D Machine Vision Revolutionizes EV Production

Our partnership with LMI is more than just words and good ideas. We have a proud history of staying at the forefront of automotive manufacturing through successful automation deployment. We worked in tandem with a tier 1 automotive supplier manufacturing battery components and other parts for leading electric vehicle OEMs.

Their challenges with EVs were immediately apparent. The battery components are large, often taking up the entire undercarriage of a modern electric vehicle. This led to warpage during manufacturing, putting components out of geometric tolerance. For drilling and reinforcement, each complete battery cell has hundreds of individual holes, all of which require positioning precision and parallelism from top to bottom. In this situation, traditional contact gauging methods—both by hand and more automated solutions—were neither feasible nor reliable on the scale this client required.

We integrated an LMI laser line profiler and other sensors into our custom engineered automated inspection cell. This gave our client the ability to inspect the entire battery part for hundreds of data points with remarkable speed. The client was thrilled with their new 3D measurement capability, especially the new functionality to evaluate part condition so quickly.

Once the system was up and running, even more benefits became apparent. The integrated nature of a +Vantage system built with LMI vision technology makes them highly flexible and easy to retool for new manufacturing processes. Our design philosophy of long-term reliability also means minimal downtime to fix and maintain inspection cells.

Contact Us

Are you ready to move forward with a non-contact inspection system? Do you already have an application in mind for +Vantage Automation and LMI Vision products? Contact us today so our dedicated engineering staff can evaluate your needs and start working on a solution that’s right for you!