How Assembly and Test Automation Helps Scale New & Existing Technologies for Battery Manufacturers

Electric vehicle (EV) production presents numerous challenges, particularly when it comes to manufacturing high-performance batteries.

The EV battery assembly process requires precise assembly of complex components. The intricate nature of battery production demands a stringently controlled manufacturing process, including thorough inspection, accurate assembly, and quality control measures to ensure reliability and efficiency in every battery.

Here, we examine how assembly and test automation help lithium-ion battery manufacturers scale new and existing technologies for precision assembly.

EV Battery Production

One of the primary complexities in electric vehicle battery production is ensuring the precise assembly of individual cells, a key component of EV batteries.

One of the primary complexities in electric vehicle battery production is ensuring the precise assembly of individual cells, a key component of EV batteries.

Each battery cell must be precisely aligned and connected to form a functional battery pack. This process requires advanced automation, as human hands typically lack the precision needed for this critical task.

Additionally, the need for advanced materials further adds to the complexities of battery production. Manufacturers must source and handle these raw materials with care and accuracy.

EV Battery Inspection

EV battery inspection is another crucial aspect of the production process. Through meticulous measurement and process control, manufacturers can ensure that each battery meets specific quality standards. This not only guarantees the effectiveness of electric vehicle batteries but also minimizes waste and reduces the likelihood of faulty products reaching the market.

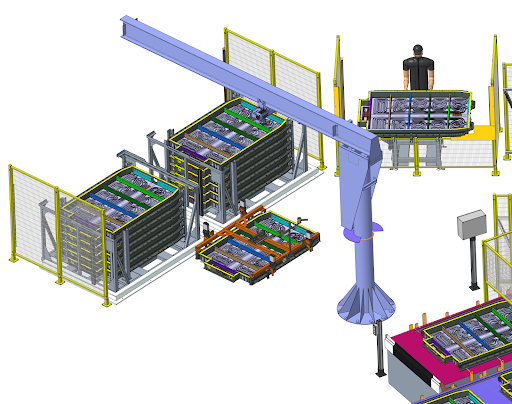

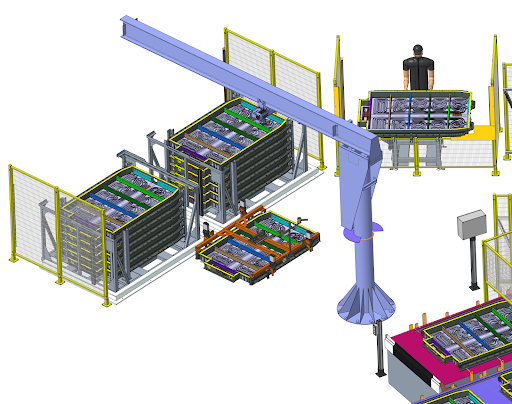

To address these complexities, automation plays a crucial role in ensuring precision, efficiency, and consistency in the assembly of intricate components, such as EV batteries. High-speed in-line metrology allows manufacturers to automate the inspection process while collecting and analyzing data to catch errors and facilitate continuous improvement.

Technological advancements—including robotic arms and advanced machinery—have significantly contributed to enhancing efficiency in the production line. By leveraging automation technologies, manufacturers can reduce errors and minimize waste in the manufacturing process, ultimately leading to higher-quality end products.

Automation and High-Precision Assembly

Automation technology enables high-precision assembly, such as the alignment and connection of individual cells, which is necessary for the seamless functionality of battery packs in EVs.

Automation technology enables high-precision assembly, such as the alignment and connection of individual cells, which is necessary for the seamless functionality of battery packs in EVs.

These technologies also provide safety benefits by handling potentially hazardous materials during the EV battery assembly process, minimizing the risk to human workers and ensuring a safer working environment.

Implementing assembly automation also enables manufacturers to scale up production to meet the growing demand for EVs. As the market continues to shift towards electric mobility, the need for efficient and scalable production processes has become increasingly crucial.

Automation not only facilitates higher production volumes but also allows for consistent battery quality control and adherence to strict manufacturing standards.

Examples of Automation for Battery Manufacturing

Several successful examples of implementing assembly automation in the battery manufacturing process already exist, demonstrating how manufacturers have overcome these challenges.

Several successful examples of implementing assembly automation in the battery manufacturing process already exist, demonstrating how manufacturers have overcome these challenges.

Companies have leveraged automation technologies for the EV battery assembly process to significantly improve production processes, leading to higher output and improved battery quality. These success stories serve as a testament to the effectiveness of automation in addressing the challenges of battery production for EVs.

For example:

Download Your Free eBook on EV Battery Manufacturing

As the market for electric mobility continues to expand, the role of automation in electric battery production will only grow in significance, providing manufacturers with the means to meet the increasing demand for high-performance electric vehicle batteries.

Want to learn more about EV battery assembly automation? Download your copy of our free ebook on EV battery manufacturing, and discover how automated solutions can streamline this process for manufacturers to meet demand and reduce operating costs.

One of the primary complexities in electric vehicle battery production is ensuring the precise assembly of individual cells, a key component of EV batteries.

One of the primary complexities in electric vehicle battery production is ensuring the precise assembly of individual cells, a key component of EV batteries. Automation technology enables high-precision assembly, such as the alignment and connection of individual cells, which is necessary for the seamless functionality of battery packs in EVs.

Automation technology enables high-precision assembly, such as the alignment and connection of individual cells, which is necessary for the seamless functionality of battery packs in EVs. Several successful examples of implementing assembly automation in the battery manufacturing process already exist, demonstrating how manufacturers have overcome these challenges.

Several successful examples of implementing assembly automation in the battery manufacturing process already exist, demonstrating how manufacturers have overcome these challenges.