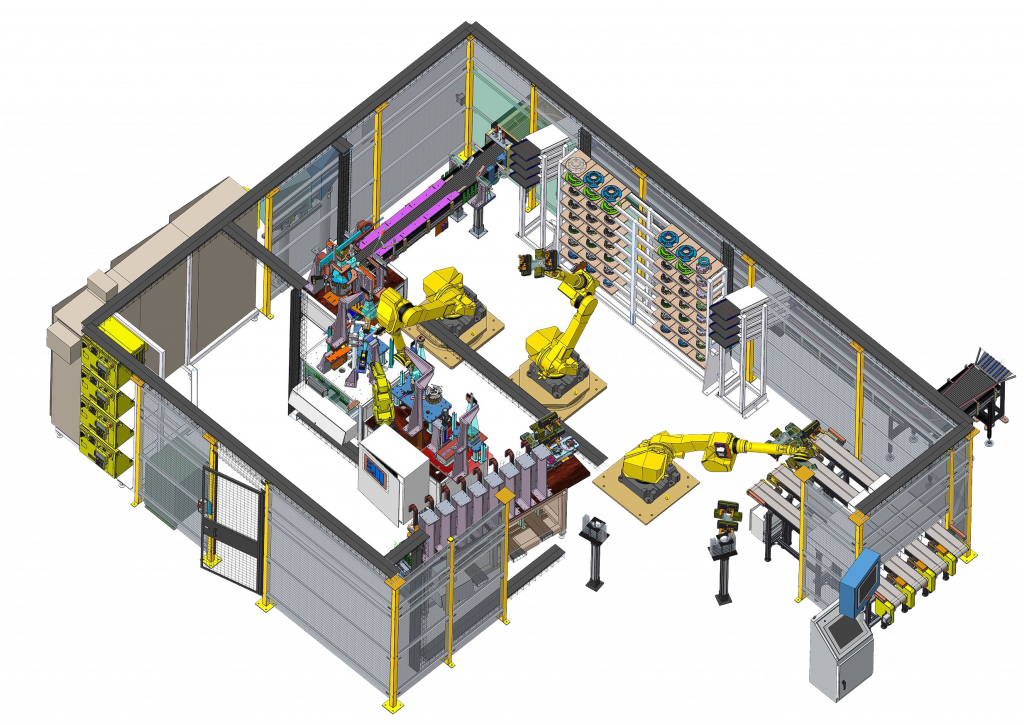

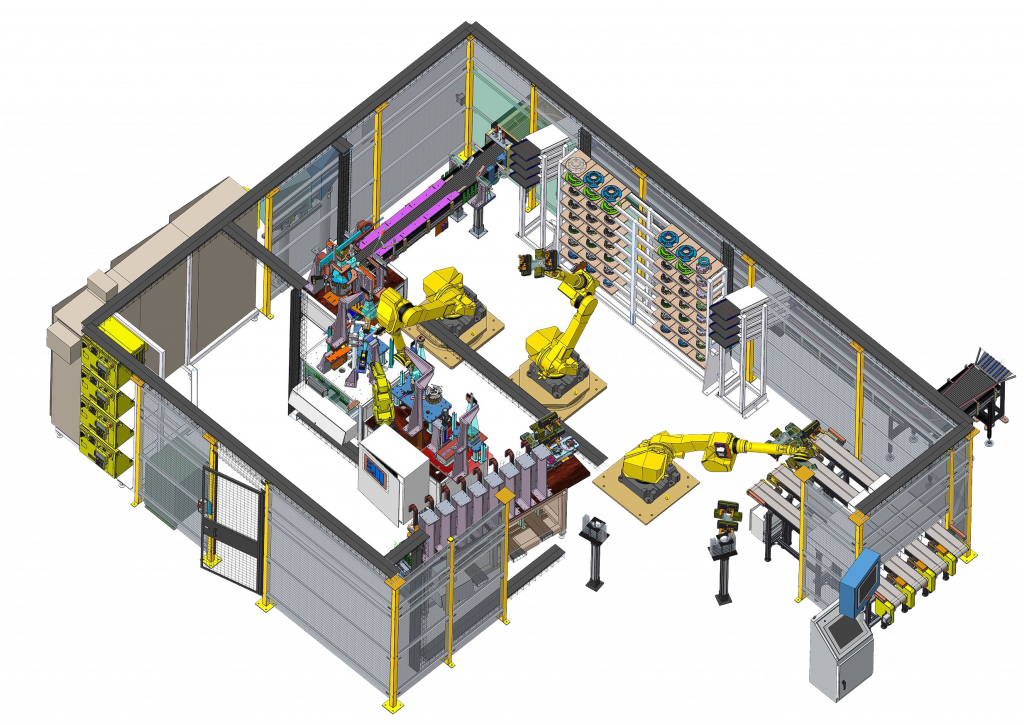

+Vantage Corporation aims to provide you with fully integrated solutions for end of line testing including inspection, leak testing and assembly of sub-components. As your materials move through the assembly process, they’ll likely pass through the hands of numerous machines produced by numerous firms, each performing a specific task. +Vantage provides all these services as a single-source supplier, simplifying your equipment purchasing, repair procedures and point of contact communication.

+Vantage Corporation aims to provide you with fully integrated solutions for end of line testing including inspection, leak testing and assembly of sub-components. As your materials move through the assembly process, they’ll likely pass through the hands of numerous machines produced by numerous firms, each performing a specific task. +Vantage provides all these services as a single-source supplier, simplifying your equipment purchasing, repair procedures and point of contact communication.

Inspection

We’re proud to offer 100% automated inspection systems for your production lines, and at the end of line stage, that automatic testing is more important than ever. +Vantage offers linear variable displacement transducers (LVDT’s) for GD&T based measurements, giving you the ability to measure your components directly against the master CAD model and set tolerances for pass/fail criteria. Our air gauge inspection systems get into corners an LVDT can’t reach and provide highly accurate, non-contact inner diameter and outer diameter shaft measurements. The air-to-electric transducer for our air gauge systems is produced in-house, one more bespoke element we’ve developed to best meet our customer’s needs. Vision inspection goes hand in hand with contact and transducer based methodologies, and we incorporate custom lensing and top quality components from partners like Cognex, Datalogic, LMI Technologies, and more.

Leak Testing

For watertight components or assemblies expected to operate in a fully immersed environment, leak testing is paramount. Leak testing can take numerous different forms. Among the most common automated methods is pressure decay testing, which pressurizes the test article and then measures any drop in pressure to identify leaks. This test is exceptionally simple to automate, and one which we do frequently for our clients. Pressure testing may be inverted in a variant of the test known as vacuum decay testing, for components which are expected to hold under vacuum rather than positive pressure, and for more intensive applications, specialty leak test methodologies like helium and halogen based tests can be employed for your system.

Sub Component Assembly

The end of line stage in your process may not be solely reserved for inspection, but also the final assembly of sub-components. As a turnkey supplier of automated systems, +Vantage is ideally suited for integrating assembly and inspection systems. Our torque and fastening systems can operate in a blow fed or track fed manner, while the system will automatically monitor torque and angle measurements in real time for process control. Pressing systems can be built in numerous configurations, from servo driven to hydraulic driven, pneumatic or air over oil, all backed up by our in-house finite element analysis (FEA). Riveting and RTV dispensing can be built in similarly extensive configurations, while our conveyors and part handling systems come in every shape and size, from robotic handling and custom end of arm tooling to your more traditional gravity and power roller systems.

The Single Source Difference

All of these systems are well and good as is, but what sets a system from +Vantage Corp apart from the competition is our single source methodology. We act as the system integrator and single source supplier for each system we produce, revolutionizing and simplifying the supply chain for every customer downriver of us.

Common Equipment

Because we act as a single source supplier, all of our equipment is designed for intercompatibility, eliminating the headache of conferring with multiple vendors as to whether their systems can be intermeshed and removing the further possibility of pass through systems.

Commonality in Spare Parts

We all know the headache of trying to order a spare part for the system, finding it in your back end, and calling up the distributor only to find out that you need to call the OEM since they don’t stock it anymore. And now the distributor’s part number isn’t the OEM’s part number, or maybe the distributor changed part numbers a decade ago and now your component is functionally untraceable from the OEM’s perspective. It’s a tale as old as time, but it shouldn’t be. With +Vantage as your system integrator, there’s commonality across all our part numbers, providing ease of sourcing for any spare parts you need. No more headaches, simple as that.

Single Point of Contact

With +Vantage as your single supplier, you only need one point of contact for all your needs. Whether it’s developing and installing a new system, ordering spare parts, troubleshooting, or adding our services for project management, we condense the job of numerous firms down to one, streamlining your process. If you have any questions or want to get started on something new, please reach out so our dedicated engineering team can get back to you!

+Vantage Corporation aims to provide you with fully integrated solutions for end of line testing including inspection, leak testing and assembly of sub-components. As your materials move through the assembly process, they’ll likely pass through the hands of numerous machines produced by numerous firms, each performing a specific task. +Vantage provides all these services as a single-source supplier, simplifying your equipment purchasing, repair procedures and point of contact communication.

+Vantage Corporation aims to provide you with fully integrated solutions for end of line testing including inspection, leak testing and assembly of sub-components. As your materials move through the assembly process, they’ll likely pass through the hands of numerous machines produced by numerous firms, each performing a specific task. +Vantage provides all these services as a single-source supplier, simplifying your equipment purchasing, repair procedures and point of contact communication.