Automotive Manufacturing: Automation Adoption

Since its inception, the automotive industry has led the world in manufacturing efficiency. From Ford’s automotive assembly line to today’s robotic manufacturing automation, the auto industry thrives on maximizing and optimizing its production processes.

In the modern automotive assembly and manufacturing process, manufacturers entrust most tasks to robots. Automation systems are simply more cost-effective than human employees in the long-run. With today’s cutting edge technology, manufacturers can repurpose and reprogram their robots to adapt to new production programs, feeding market demands for years to come.

With RōBEX automotive assembly solutions, automotive manufacturers can achieve new levels of efficiency with fewer defects and lower costs per unit.

RōBEX Automotive Automation Solutions

With advances in robotics technology, manufacturers can automate more automotive assembly and manufacturing tasks than ever. Some of the automation solutions that RōBEX offers include:

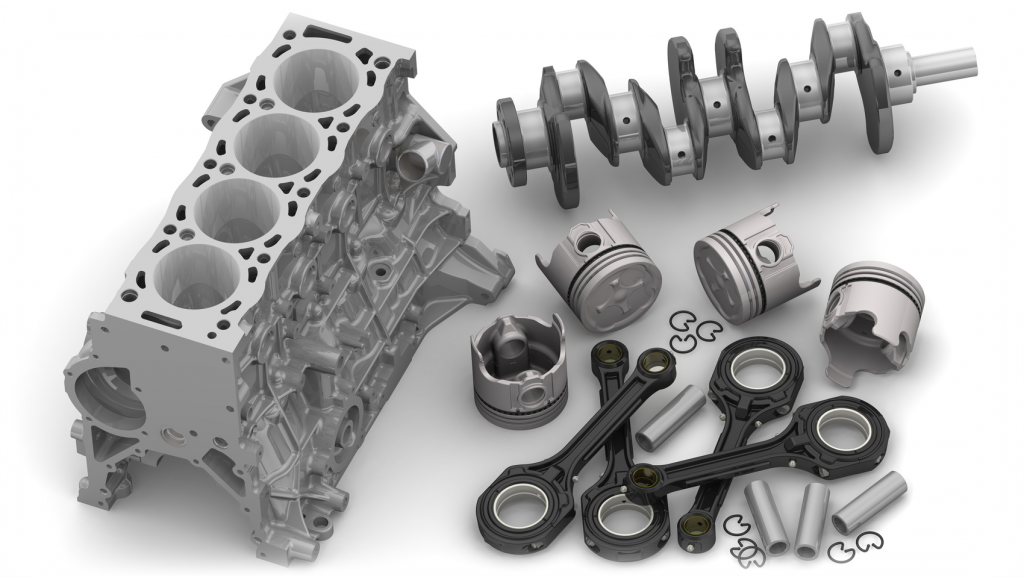

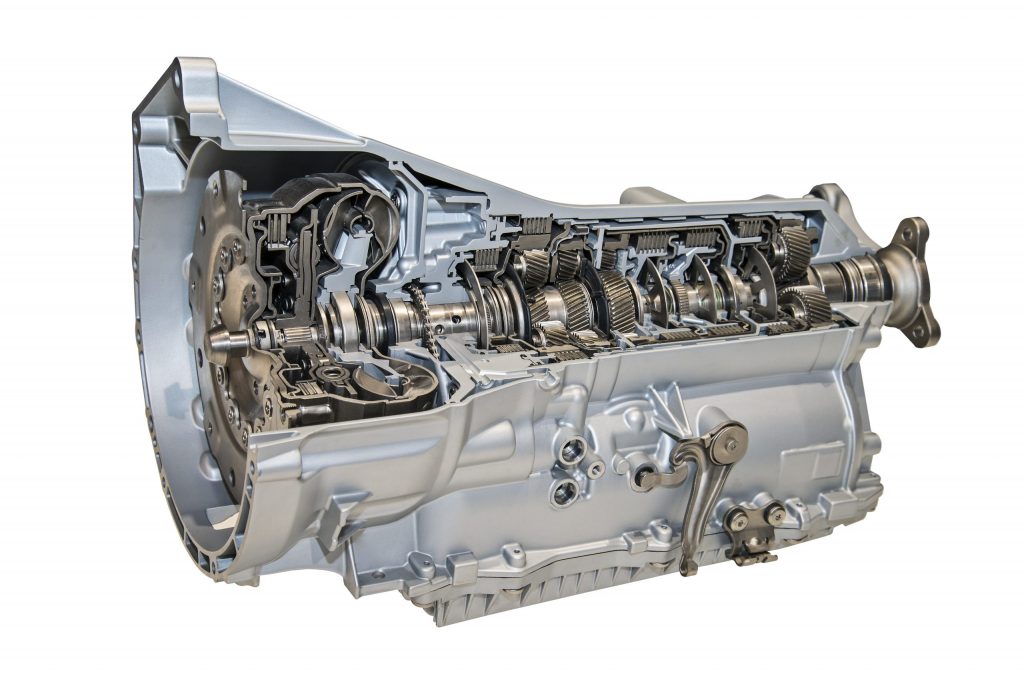

- Assembly of various automotive components

- Inspection & measurement of critical components

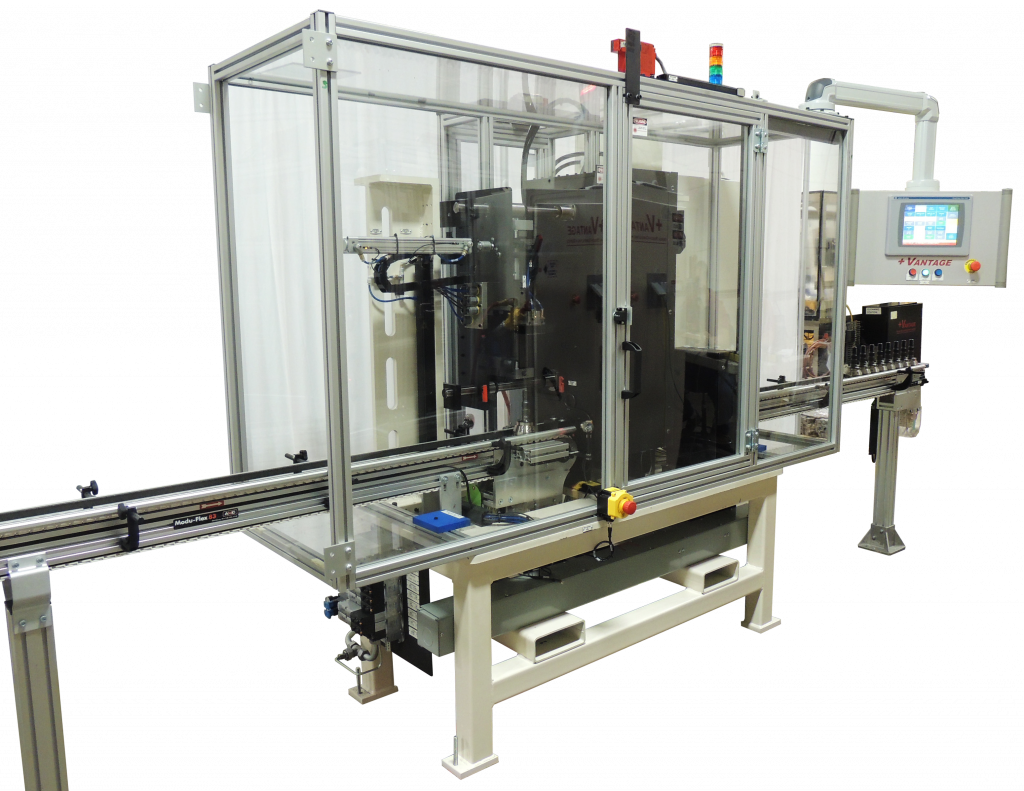

- 100% inline inspection equipment

- Transfer of parts from one machine to another

- Press automation

- Part inspection

- Leak testing

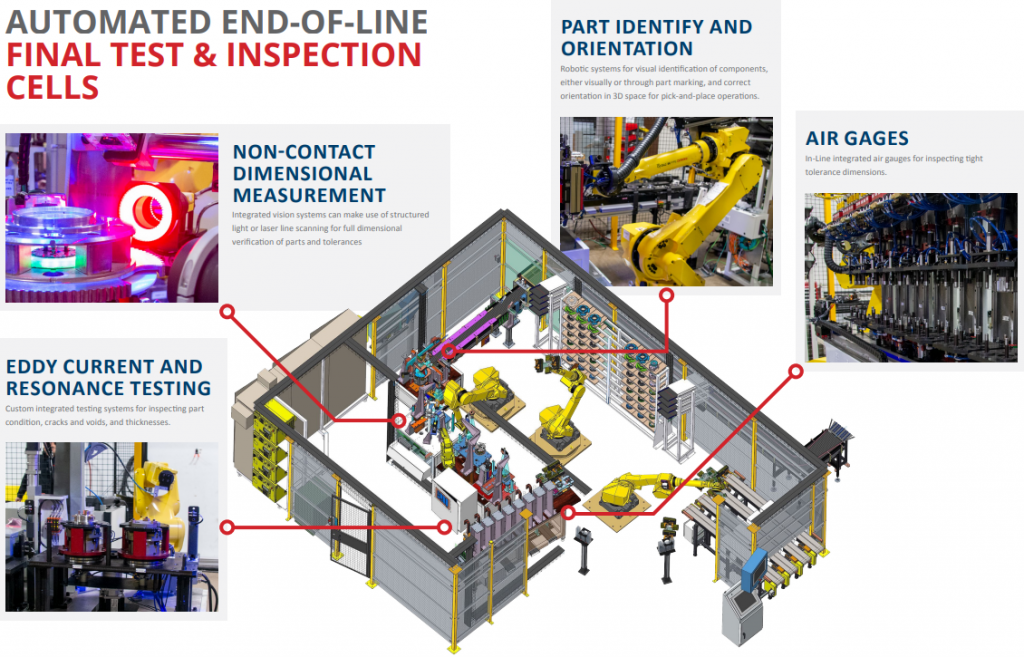

- End of line testing cells

- Laser marking & part serialization

- CNC machine tending and manufacturing automation