At +Vantage Corporation, we’re proud to be your single source system integrator for every system we produce. From assembly and part making solutions like pressing and riveting, to inspection and testing, and turnkey part handling, we have you covered.

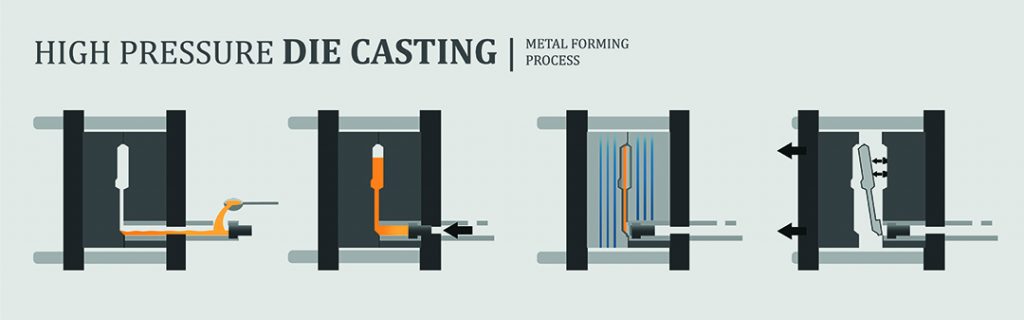

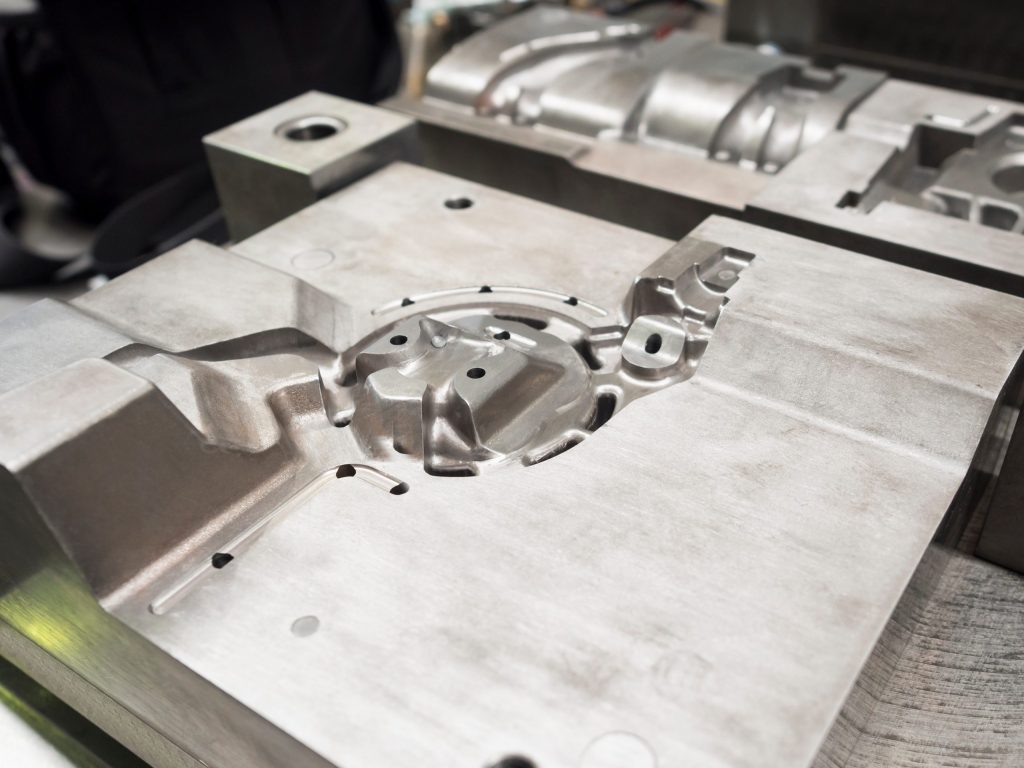

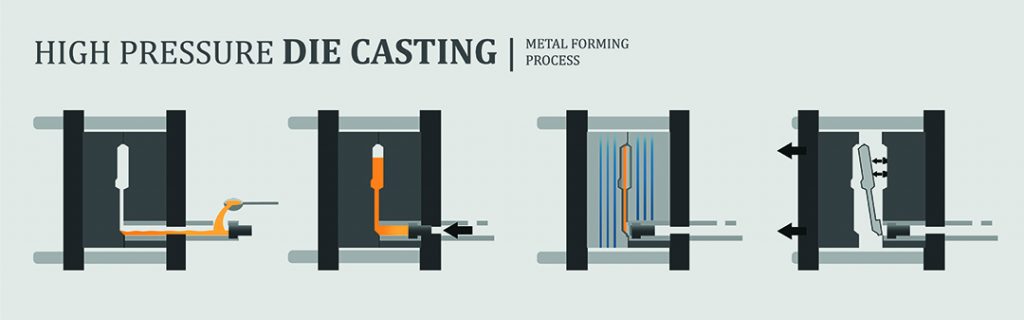

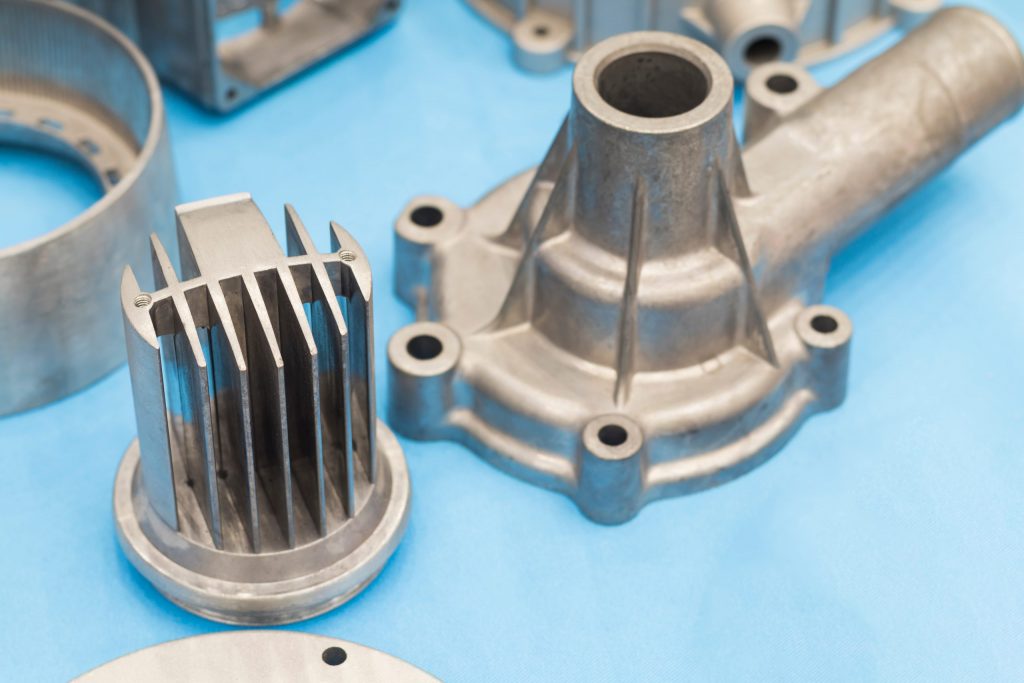

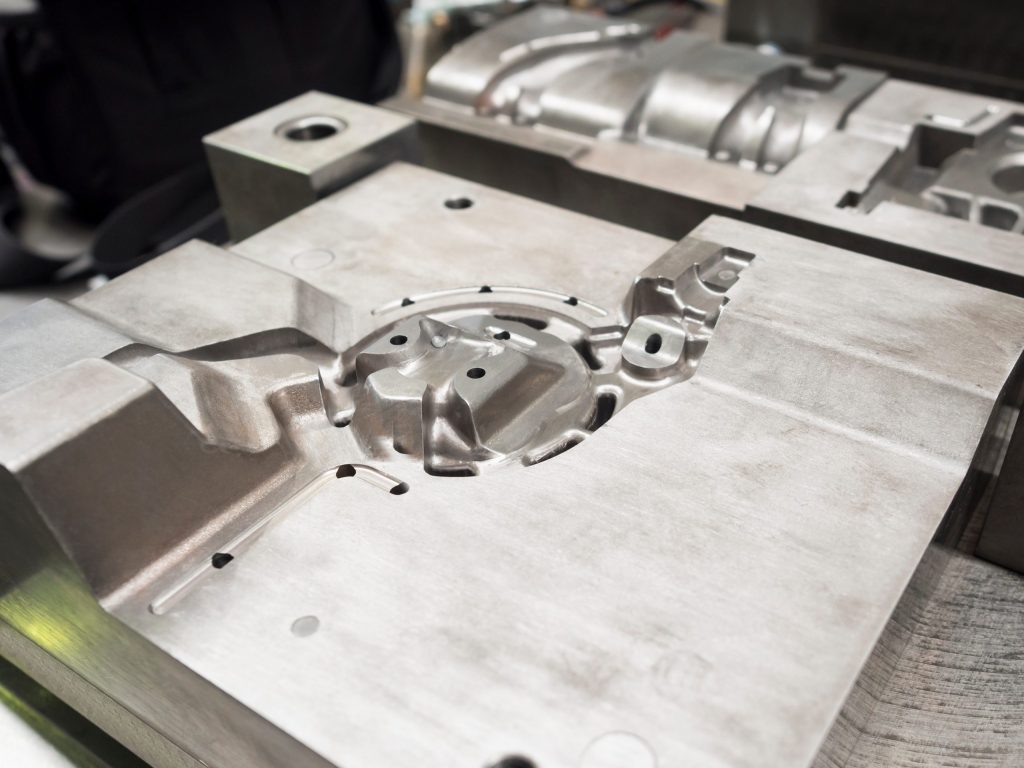

Today we want to focus on another technology available to you for manufacturing: High Pressure Die Casting. Otherwise known as HPDC, high pressure die casting uses a method similar to plastic injection molding, wherein a mold with a cavity in the shape of the finished product is injected with molten metal under immense pressure.

This process occurs in well under a second, injecting the metal at pressures upwards of 1,000 bar, or 14,500 PSI. HPDC is applicable to steel, zinc, copper, lead, aluminum, magnesium and more. +Vantage offers you the tools and techniques to successfully integrate HPDC into your manufacturing process, saving you time and increasing efficiency.

The +Vantage Process

We don’t simply believe in automating a portion of your high pressure die casting system, but rather working with you to develop a fully integrated HPDC process. Our automation supports your process all the way from first pour through final packout, and every stage in between.

Robotic Pour

The HPDC process begins with our robotic pouring systems, which allow for complete control in either kilograms or pounds. Customizable parameters for your product include bucket preheat and warm up, drip angle position and filling offset, among many others. This data is maintained through the touch screen HMI, which also controls the furnace sweeping programs for routine maintenance.

Robotic Degate

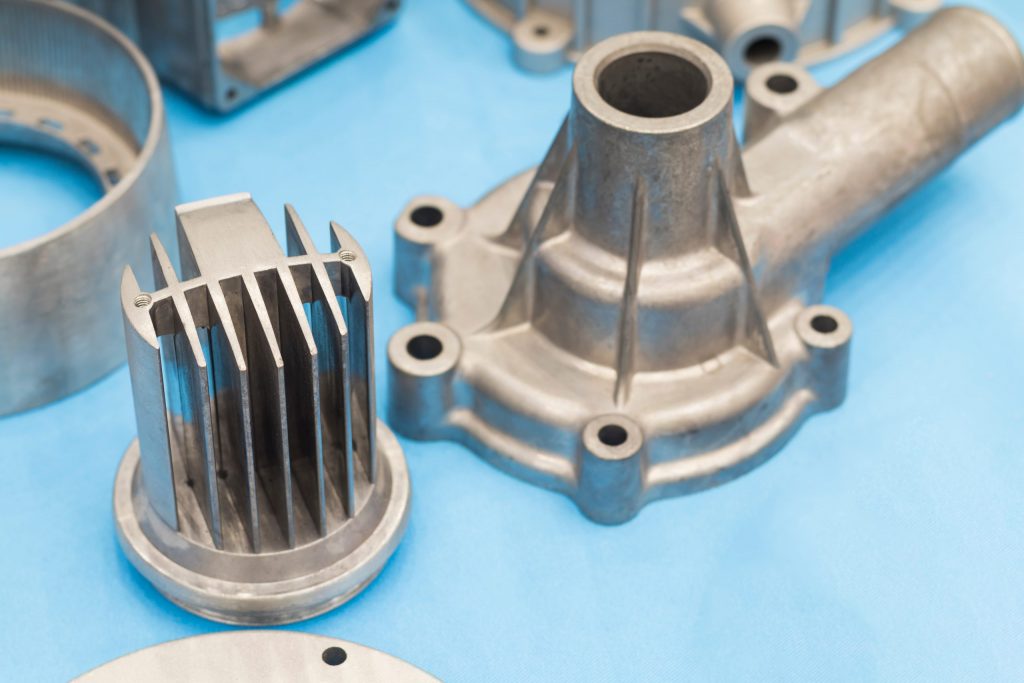

Once the part has been successfully cast, we can seamlessly hand off components to a robotic tool cell for degating. Custom-programmed robotic tool paths remove pieces with ease within welded steel enclosures for operator safety. For efficiency, multiple prototype samples are tested for optimized removal of material.

Laser Marketing and Traceability

Complete part traceability is a priority here at +Vantage, and we offer numerous ways to achieve it. Inkjetting, laser marking, dot peening and more are all available. All of our part-marking functions can be used to automatically intake part numbers from your MES system, and export into your PLM suite.

Our laser marking systems for HPDC are specifically ruggedized for die casting environments, and give you the capability to trace a part back to the individual die shot. In keeping with our commitment to safety, our laser marking systems include robotic arms for automated handoff, removing hazards to the operators while the parts are still hot.

Automated CNC Loading

Die casting is often only the first component of a manufacturing process. While degate may remove the excess material from the pour, final CNC finishing may be required for fine details. Our turnkey automated handoff systems are customized for every client, and include integrated traceability, giving you the fidelity to identify not just what part has sustained a defect, but exactly where in your process it originated.

Full HPDC Inspection Systems

Inspection systems are as important to a product as the systems which manufacture it, and we don’t skimp on in-line inspection technology at +Vantage. We integrate inspection technology before the CNC stage, giving you the ability to measure core pin depth, chunk out, warpage, excessive flashing, and other defects. This comprehensive inspection helps you identify failed components before you invest further hours into them.

After final manufacturing and machining is complete, a +Vantage system comes the full suite of inspection steps. Leak testing with pressure decay systems ensures part integrity. Dimensional inspection gages—developed specifically for die cast components—inspect bores and part features relative to your pre-defined datums, as well as warpage, flatness and parallelism. 2D and 3D inspection systems measure part surfaces to identify porosity, chunk-out, and cracking.

Assembly and Pack Out

Final assembly of your HPDC components is also accomplished autonomously through the myriad integrated assembly cells we offer. Insertion of towel pins, bushings, ball plugs, rivets and nuts can all be installed, as well as torquing fasteners and installation of sealing material. For packout, automated systems track the part numbers of every individual unit in shipment, maintaining traceability from start to finish down to each unique part number.

The +Vantage Advantage

High Pressure Die Casting is an important process in large volume manufacturing. Its benefits become even more pronounced when they are seamlessly integrated for speed, efficiency, quality, and safety.

Every system we’ve discussed can be fully robotic or manual, depending on the needs of your product and process. No matter the industry or size of your company, +Vantage offers powerful solutions. If you want to learn more, download the Automation for High Pressure Die Casting eBook today!