Automation Systems & Equipment Are Taking Massive Strides With Industry 4.0

Today’s market requires constantly accelerating production volumes, and that is changing the way manufacturing plants are run. The modern factory is built on Industry 4.0, and that means full automation integration. Right now, early adopters are enjoying a serious edge. Thanks to manufacturing automation equipment, assembly lines can be faster, more accurate, and better for workers than ever before.

With cheaper, more flexible solutions entering the market each year, powerful automation is now available even to smaller companies. Keep reading to discover the new trends in manufacturing automation that are transforming the industry.

New Developments to Watch in Assembly Line Automation

Continuous, 24-Hour Operation is Becoming Easier Than Ever

Around-the-clock operation isn’t a new concept, but it has traditionally been a logistical nightmare for companies. Luckily for manufacturers, many of the most important roles in assembly, testing, and even maintenance can now be performed by machines. Automated cells and equipment allow for reduced labor costs, seamless shift transitions, and increased satisfaction for workers. While we are still some ways out from true lights-out manufacturing, automation is allowing companies to work longer hours more productively, and with reduced downtime.

Around-the-clock operation isn’t a new concept, but it has traditionally been a logistical nightmare for companies. Luckily for manufacturers, many of the most important roles in assembly, testing, and even maintenance can now be performed by machines. Automated cells and equipment allow for reduced labor costs, seamless shift transitions, and increased satisfaction for workers. While we are still some ways out from true lights-out manufacturing, automation is allowing companies to work longer hours more productively, and with reduced downtime.

In-Depth Process Control is Transforming How Manufacturers Control Production

Traditionally, precision parts have been tracked through offline tests, conducted by trained technicians. This can give an indication of the quality of parts, but it can also mean tolerance errors aren’t caught until far too late. As modern industrial automation equipment accelerates production speeds, this risk is only increased. This is where automated sensor and data processing equipment step in.

Integrating sensors into the production line allows for unprecedented supervision over every single part made. Statistical Process Control (SPC) software provides manufacturers the tools to carefully track part quality, giving them the power to identify trends and address issues before they even arise.

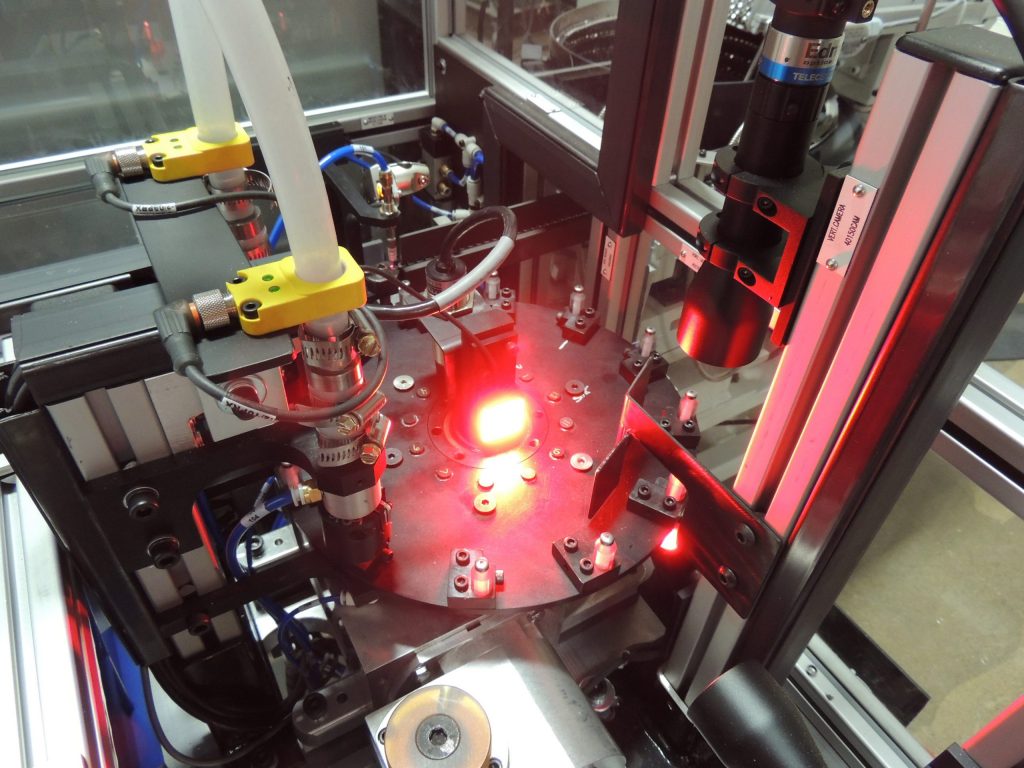

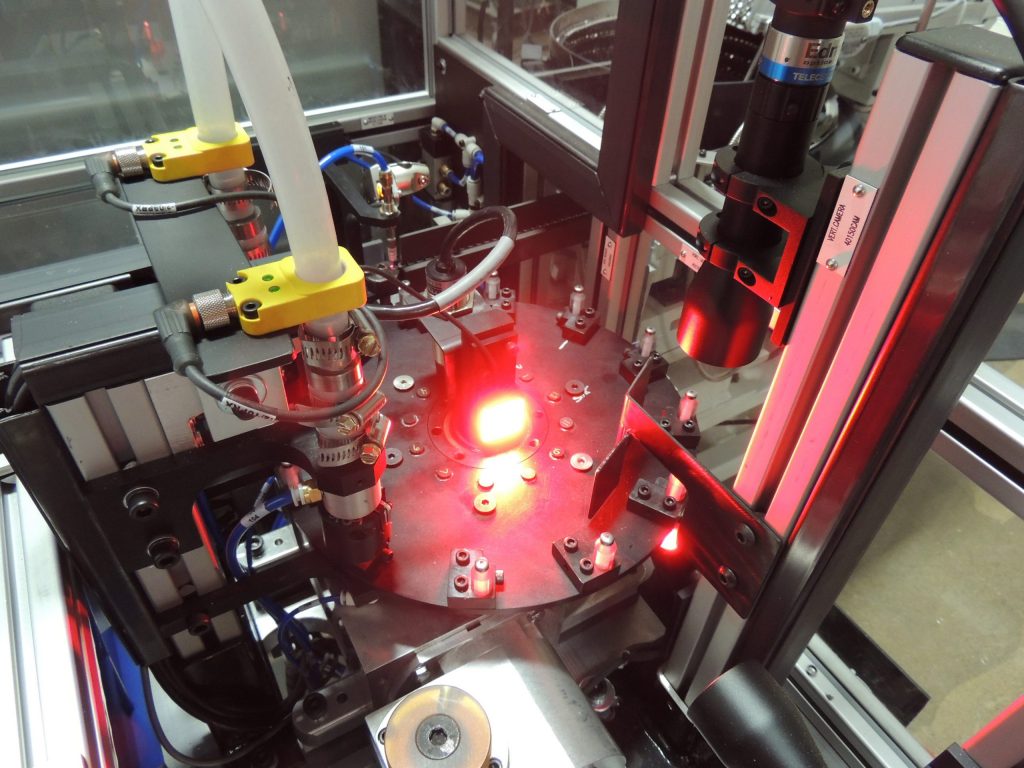

Innovations in Visual Inspection Are Changing High-Volume Production

When dealing with bulk products, the importance of fast, accurate inspection cannot be overstated. In the past, trained technicians would select and test random pieces manually, ensuring they fit tolerance. However, with modern manufacturing process automation, a production error that isn’t caught immediately can lead to hundreds or thousands of unusable parts. In-line visual inspection systems ensure that doesn’t happen.

When dealing with bulk products, the importance of fast, accurate inspection cannot be overstated. In the past, trained technicians would select and test random pieces manually, ensuring they fit tolerance. However, with modern manufacturing process automation, a production error that isn’t caught immediately can lead to hundreds or thousands of unusable parts. In-line visual inspection systems ensure that doesn’t happen.

2D Inspection

2D inspection systems allow for rapid testing of dozens of random parts every minute. These systems provide high-resolution measurements, and can easily identify faulty parts and feed tolerance trends into process control software. Watch a video of this +Vantage High-Speed Strut Inspection and Sorting System to witness the power of bulk inspection automation.

3D Inspection

3D inspection systems provide easy pass-fail solutions for complex parts, determining the depth of flaws and distortions with incredible accuracy. These systems are also capable of detailed mapping to provide incredibly accurate data for parts.

On-Machine Sensors Are Revolutionizing Precision and Maintenance

The constant stresses of automated production mean tools experience constant wear. This is especially true in the case of automated computer numerical control (CNC) tools, where machining bits wear down over hundreds and thousands of parts. As a result, pieces will drift further and further from tolerance over time. In the past, this has meant costly downtime for maintenance and tool replacement. Now, integrated metrology is offering new solutions.

+Vantage machines utilize cutting-edge, on-machine sensors to detect wear and adjust accordingly. Our process control software allows for real-time tool compensation data to prolong tool life and facilitate intelligent maintenance, improving uptime. This increased level of control provides a better process for the manufacturer and better results for customers.

Flexible Systems Are Providing Unprecedented Changeover and Upgrade Efficiency

The future of automation systems and equipment is in flexibility. Specialized, single-function machines might be ideal for established, high-volume processes, but the landscape of manufacturing is changing. More and more, smaller manufacturers are looking to integrate, and they need solutions that will accommodate a shifting market. Developments such as robotic assembly arms allow these companies to fully embrace the power of industrial automation.

The future of automation systems and equipment is in flexibility. Specialized, single-function machines might be ideal for established, high-volume processes, but the landscape of manufacturing is changing. More and more, smaller manufacturers are looking to integrate, and they need solutions that will accommodate a shifting market. Developments such as robotic assembly arms allow these companies to fully embrace the power of industrial automation.

The Benefits of Flexible Automation Equipment

There are three key factors that make the flexible automation production line superior. The first is the easy development of products with ever-changing requirements. Flexible systems make the process as simple as a new software, robot program, or PLC program update. This leads to the second benefit: customized products from turnkey solutions.

The second benefit is that turnkey systems are far cheaper than custom machines. Flexible robotic solutions can be configured to produce a wide range of products, giving companies an affordable route to automation. Even when systems need to be configured beyond their original settings, we offer a full suite of project management and support services for retooling manufacturing lines and starting new products.

The final benefit is seamless application of process control insights. As mentioned above, flexible systems allow tool compensation data and inspection data to be fed directly back into the process, increasing precision, quality, and uptime in any CNC or production process.

Automate with Us!

Are you ready to revolutionize your manufacturing process? Visit our website to learn about the detailed +Vantage integration process and the vast array of automation services we offer. To discuss how our systems can benefit your custom process, contact us to speak with an engineering design consultant today!

Around-the-clock operation isn’t a new concept, but it has traditionally been a logistical nightmare for companies. Luckily for manufacturers, many of the most important roles in assembly, testing, and even maintenance can now be performed by machines.

Around-the-clock operation isn’t a new concept, but it has traditionally been a logistical nightmare for companies. Luckily for manufacturers, many of the most important roles in assembly, testing, and even maintenance can now be performed by machines.  When dealing with bulk products, the importance of fast,

When dealing with bulk products, the importance of fast,  The future of automation systems and equipment is in flexibility. Specialized, single-function machines might be ideal for established, high-volume processes, but the landscape of manufacturing is changing. More and more, smaller manufacturers are looking to integrate, and they need solutions that will accommodate a shifting market. Developments such as

The future of automation systems and equipment is in flexibility. Specialized, single-function machines might be ideal for established, high-volume processes, but the landscape of manufacturing is changing. More and more, smaller manufacturers are looking to integrate, and they need solutions that will accommodate a shifting market. Developments such as